How Much Weight Can Extruded Aluminum Hold

Extruded aluminum is a strong and durable metal that can hold a significant amount of weight. It is often used in construction and other applications where strength and durability are required. Extruded aluminum has a high resistance to corrosion and is also weather-resistant, making it an ideal choice for outdoor use.

Extruded aluminum is a strong and lightweight material that can be used for a variety of applications. It is often used in the construction of aircraft and other vehicles where weight is a critical factor. But just how much weight can extrude aluminum hold?

The answer to this question depends on a number of factors, including the thickness of the aluminum, the type of alloy, and the amount of stress that is applied to the metal. In general, however, extruded aluminum can support a significant amount of weight. For example, an aluminum beam that is just one inch thick can support up to four hundred pounds without bending or breaking.

And if the beam is thicker, it can support even more weight. This makes extruded aluminum an excellent choice for many structural applications. So, if you’re looking for a strong and lightweight material for your next project, consider using extruded aluminum.

It’s sure to hold up under whatever load you need it to carry.

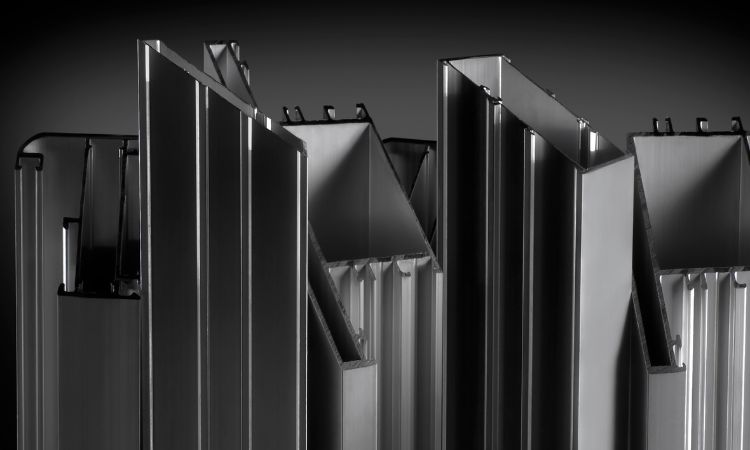

Aluminum Cabinetry – Part 1: Profiles | Ultimate Guide to 8020 Aluminum Extrusion

Aluminium Profile Load Capacity

Aluminum profiles are commonly used in a variety of applications, from construction to automotive manufacturing. While aluminum is strong and lightweight, it is important to know the load capacity of an aluminum profile before using it in your application. The load capacity of an aluminum profile is determined by its cross-sectional area.

The larger the cross-sectional area, the greater the load capacity. Other factors that can affect the load capacity of an aluminum profile include the type of alloy used and the tempering process. When selecting an aluminum profile for your application, be sure to consider its load capacity to ensure it can safely support the weight or force you need it to.

How Strong is 2020 Aluminum Extrusion

In aluminum extrusion, the term “2020” refers to a standard size of extruded aluminum tubing. 2020 aluminum is strong and lightweight, making it a popular choice for many applications. Here’s a look at the strength of 2020 aluminum extrusion.

The Ultimate Strength of 2020 Aluminum Extrusion

The yield strength of annealed 2024-T4 and T851 temper Alloys is 30 ksi (205 MPa) and 35 ksi (241 MPa), respectively. The ultimate tensile strengths are 52-56 ksi (359-386 MPa) for both tempers.

Yield strengths increase with aging time up to 4 h at 150°C (300°F). For longer aging periods, the yield strength decreases but approaches a constant value after about 16 h of aging.

Aluminum Extrusion Strength Calculator

If you are looking for an aluminum extrusion strength calculator, there are a few different places that you can find one. One option is to search for one online. There are a variety of websites that offer this type of calculator, so you should be able to find one that meets your needs.

Another option is to purchase an aluminum extrusion strength calculator software program. These programs are designed to help you calculate the strength of aluminum extrusions. They usually come with a variety of different options and features, so you will want to make sure that the program you choose has the features that you need.

Once you have found an aluminum extrusion strength calculator, using it is fairly simple. You will just need to input the dimensions of the aluminum extrusion into the calculator and it will do the rest. It will provide you with a report that includes the maximum load capacity and minimum deflection value for the aluminum extrusion.

Using an aluminum extrusion strength calculator can be very helpful when trying to determine how strong an aluminum extrusion is. By having this information, you can make sure that your project is up to code and safe for use.

T-Slot Weight Capacity

If you’re looking for a table with a high weight capacity, T-slot tables are the way to go. T-slot tables have a unique design that allows them to support heavy loads without compromising on stability. The T-shaped slots in the table top provide extra support for heavy items, making these tables ideal for use in industrial or commercial settings.

Here’s what you need to know about T-slot tables and their weight capacities: The size of the T-slot plays a big role in determining the maximum weight capacity of the table. The larger the slot, the more support it can provide for heavier items.

That’s why most industrial T-slot tables have large slots that can accommodate plenty of weight. However, it’s not just the size of the slot that determines how much weight a table can hold. The material used to construct the table also makes a difference.

Stronger materials like steel or aluminum will be able to support more weight than weaker materials like wood or plastic. When choosing a T-slot table, be sure to consider both the size of the slot and the strength of the material before making your final decision. With all that being said, what is the average maximum weight capacity for a typical T-slot table?

Most commercially available models are rated for weights between 500 and 1,000 pounds. However, there are some special models that can accommodate even heavier loads – up to 2,000 pounds or more! If you need a particularly sturdy table, make sure to look for one of these higher-capacity models.

When shopping for a new T-slot table, keep these tips in mind to ensure you choose one with an appropriate weight limit for your needs. With their strong construction and large load capacities, T-slot tables are an excellent choice for anyone who needs a durable and reliable work surface.

Extrusion Load Calculation

Extrusion load calculation is a process used to determine the amount of force required to push an object through a die or other opening. The size and shape of the object, as well as the material it is made from, are all factors that must be considered in order to accurately calculate the extrusion load.

There are several methods that can be used to calculate extrusion loads, but the most common is the use of computer software.

This software takes into account all of the variables mentioned above and provides a result that can be used to determine the necessary force required for successful extrusion.

Extrusion loading calculations are an important part of any manufacturing process that uses this method, as they ensure that enough force is being applied to successfully create the desired product. By taking all factors into consideration and using accurate software, manufacturers can avoid costly mistakes and produce high-quality products every time.

Aluminum Load Calculator

If you are planning on carrying a load with your aluminum trailer, it is important to know how much weight it can safely hold. This aluminum load calculator will help you determine the maximum weight your trailer can carry. To use the calculator, simply enter the dimensions of your trailer (length, width, and height), and then click calculate.

The calculator will give you the maximum weight that your trailer can hold, as well as the distribution of weight across each axle. It is important to note that this calculator is only meant to be used as a guide. The actual capacity of your trailer may be different than what is calculated here due to factors such as terrain, weather conditions, and other variables.

When in doubt, always err on the side of caution and consult with a professional before attempting to carry any heavy loads.

Aluminum Channel Load Capacity Calculator

If you’re in the market for an aluminum channel load capacity calculator, you’ve come to the right place. Here at Aluminum Channel Load Capacity Calculator, we pride ourselves on providing the most accurate and user-friendly calculator available. Load capacity is an important factor to consider when choosing an aluminum channel.

The load capacity of a channel indicates how much weight it can safely support without deforming. When selecting an aluminum channel for your application, it’s important to choose one with a load capacity that exceeds the anticipated weight of your load. Our easy-to-use calculator will help you determine the maximum safe load capacity for any given aluminum channel size and thickness.

Simply enter the dimensions of the channel into our calculator, and it will do the rest. In just seconds, you’ll have all the information you need to make an informed decision about which aluminum channel is right for your project. Try our Aluminum Channel Load Capacity Calculator today, and see just how easy it is to find the perfect product for your needs!

Aluminum Extrusion Weight Per Foot

If you’re in the market for aluminum extrusions, you might be wondering about the weight of these products. After all, weight is an important factor to consider when choosing any type of material. So, how much does an aluminum extrusion weigh per foot?

Generally speaking, the weight of an aluminum extrusion will vary depending on its size and thickness. However, as a general rule of thumb, you can expect an aluminum extrusion to weigh around 0.1 pounds per foot. Of course, the actual weight of your aluminum extrusion may be slightly different than this estimate.

But overall, this should give you a good idea of what to expect when shopping for these products.

How Strong is Extruded Aluminum?

Extruded aluminum is an aluminum alloy that has been forced through a die to create the desired shape. It is one of the strongest types of aluminum, making it ideal for applications where strength is important. However, because it is so strong, extruded aluminum can be difficult to work with and may require special tools and techniques.

How Strong is 80/20 Extrusion?

80/20 extrusion is an aluminum alloy that is strong and durable. It is often used in construction and other applications where a strong material is needed. 80/20 extrusion has a high strength-to-weight ratio, making it an ideal choice for many applications.

Is Extruded Aluminum Stronger Than Steel?

There are a lot of variables to consider when trying to answer this question, including the specific alloys involved and the temper of the metals. In general, however, extruded aluminum is not as strong as steel. It is more malleable and ductile, meaning it can be easily shaped and formed but will not hold its shape as well under stress.

It is also lighter than steel, so it may be used in applications where weight is a factor.

Which is Stronger Cast Or Extruded Aluminum?

The answer to this question depends on a number of factors. Let’s take a closer look at cast and extruded aluminum to see how they compare.

Cast aluminum is made by pouring molten aluminum into a mold.

Extruded aluminum is made by forcing aluminum through a die under high pressure.

Both cast and extruded aluminum have their advantages and disadvantages. Cast aluminum is typically stronger than extruded aluminum, but it is also more expensive to produce.

Extruded aluminum is less expensive to produce, but it may not be as strong as cast aluminum.

So, which one is stronger? It really depends on your specific needs.

If you need a strong material that can withstand high loads, then cast aluminum may be the better choice. If you are looking for a less expensive option that still has good strength, then extruded aluminum may be the way to go.

Conclusion

Extruded aluminum is a type of aluminum that is used in a variety of applications. It is strong and lightweight, making it ideal for use in construction and other applications where weight is a factor. However, one question that often comes up is how much weight can extrude aluminum hold?

The answer to this question depends on a few factors, including the thickness of the aluminum and the type of load that it is being asked to support. In general, however, extruded aluminum can support quite a bit of weight. For example, it is commonly used in the construction of bridges and other structures that need to be able to support heavy loads.

So, if you are wondering how much weight extruded aluminum can hold, the answer is that it depends on several factors but, in general, it can hold quite a bit.