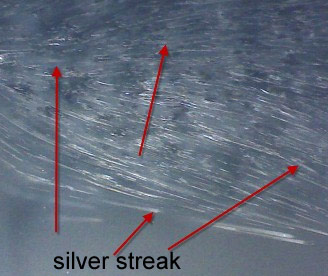

Splay is a common problem in injection molding, and can have many causes. Splay occurs when the melted plastic does not flow evenly into the mold cavity, resulting in an uneven surface on the finished part. The most common cause of splay is insufficient packing pressure.

This can be caused by a number of factors, including incorrect machine settings, worn mold components, or poor-quality plastic pellets. Other causes of splay include poor gate design, improper mold release agent application, and contaminated mold surfaces.

Splay | Injection Molding Troubleshooting

Splay is a common issue in injection molding, and can have a variety of causes. One common cause is incorrect gate location. If the gate is too close to the edge of the cavity, it can cause the plastic to flow unevenly, leading to splay.

Another potential cause is an imbalanced melt front. This can happen if there is a difference in the melting point of the different materials being used, or if one side of the mold is hotter than the other. Improper venting can also lead to splay, as it can cause pressure build-up on one side of the cavity.

If you are experiencing splay issues in your injection molded parts, it’s important to troubleshoot and identify the root cause. Once you know what is causing the problem, you can take steps to correct it and avoid future issues.

How to Get Rid of Splay in Injection Molding

If your injection molded parts are splaying, it’s likely due to a mold design flaw or improper molding settings. Splay can be prevented by ensuring that your mold has proper venting and by adjusting your injection pressure, gate size, and melt temperature.

What Causes Splay in Plastics

When plastic materials are heated, they expand. This is due to the fact that the molecules in the plastic material are moving faster as the temperature increases. When these expanded materials are cooled, they contract.

However, if cooling is not done evenly, then one side of the material will cool faster than the other side. As a result, uneven contraction can cause warping or splay in plastics.

There are several ways to avoid splay in plastics.

One way is to use annealed glass or metal molds when working with heated plastics. This will help to evenly distribute heat and prevent warping. Another way to avoid splay is by using a release agent on the mold before adding hot plastic materials.

This will help to prevent sticking and allow for easy removal of the cooled product.

Injection Molding Troubleshooting Splay

If you are having trouble with splay in your injection molded parts, there are a few things you can do to troubleshoot the issue. First, check the mold for any areas that may be causing the problem. If there are any rough spots or nicks in the mold, they will need to be repaired.

Next, check the injection pressure and speed. If they are too low, this can cause splay. Finally, check the melt temperature of the plastic.

If it is too low, this can also cause splay.

Injection Molding Shear Splay

Injection molding shear splay is a type of plastic deformation that can occur during the injection molding process. Shear splay occurs when the molten plastic is forced to flow through a narrow orifice in the mold, causing the material to deform. The resulting deformation can cause problems with the molded part, such as dimensional inaccuracy and surface imperfections.

Shear splay can be prevented by using proper mold design and injection techniques.

Deformation in Injection Molding

Injection molding is a process that can be used to create parts out of thermoplastic and thermosetting materials. In this process, molten material is injected into a mold cavity at high pressure. The material then cools and hardens inside the mold to take on the shape of the cavity.

One of the most important aspects of injection molding is understanding deformation. Deformation occurs when the molten material is injected into the mold under high pressure. This high pressure causes the material to flow, which in turn causes it to deform.

The amount of deformation that occurs depends on several factors, including:

-The type of material being injected

-The Melt Flow Index (MFI) of the material

-The injection speed

-The size and shape of the part being molded

Credit: www.injectionmoldingplastic.com

How Do You Reduce Splay in Injection Molding?

The main cause of splay in injection molding is uneven clamping force. This can be caused by a number of factors, such as an incorrect mold design, poor machine maintenance, or operator error. To reduce splay, it is important to first identify the root cause and then take steps to correct it.

One way to reduce uneven clamping force is to make sure the mold is designed correctly. The mold should have sufficient support so that it does not flex during operation. It is also important to regularly maintain the injection molding machine and make sure that all components are tight and in good working condition.

Finally, the operator should be properly trained and familiar with the machine settings and process parameters. By taking these precautions, you can minimize the risk of splay occurring during injection molding.

What is a Splay Mark?

A splay mark is a type of damage that can occur to wood. It is caused by the wood splitting or splintering along the grain. This can happen when the wood is exposed to too much moisture, or if it is not properly conditioned before use.

Splay marks can also be caused by using improper tools or techniques when working with the wood.

Splay marks are unsightly and can reduce the strength of the affected piece of wood. In some cases, they may even cause the wood to break apart completely.

If you notice a splay mark on your woodworking project, you’ll need to take steps to repair it. Depending on the severity of the damage, this might involve sanding down the area, filling it in with putty, or even replacing the affected piece entirely.

What are Common Injection Moulding Defects?

Injection moulding is a process that can be fraught with defects. Some of the most common injection moulding defects are:

1. Flash: This is when excess material is forced out of the mould during the injection process.

Flash can occur if the mould isn’t properly sealed, or if there is too much pressure or material injected into the mould.

2. Warpage: This occurs when the finished product isn’t perfectly straight or symmetrical. Warpage can be caused by uneven cooling or incorrect gate location.

3. Sink marks: These are indentations on the surface of the finished product, and are caused by uneven cooling of the plastic within the mould.

4. Voids: These are cavities within the finished product, and can be caused by poor filling of the mould or improper venting during injection.

5. Bubbles: These occur when air bubbles become trapped in the molten plastic during injection.

How Do You Prevent Voids in Injection Molding?

Voids are one of the main causes of defects in injection molded parts. They occur when there is not enough material to fill the mold cavity, resulting in an incomplete part. There are several ways to prevent voids from occurring:

1. Use a higher injection pressure. This will help to push the molten plastic into all areas of the mold cavity, reducing the chances of voids forming.

2. Use a shorter flow path.

A shorter distance for the molten plastic to travel will also reduce the chances of voids forming.

3. Increase the melt temperature. This will make the plastic more fluid and less likely to form voids as it flows into the mold cavity.

4. Use a finer-grain resin powder. A smaller particle size will allow for better filling of the mold cavity and reduce void formation.

Conclusion

There are many factors that can cause splay in injection molding, but the most common is when the melt front gets too far ahead of the pack. This can happen when the melt temperature is too high, the injection pressure is too low, or the mold temperature is too cold. If the splay is severe, it can cause the part to warp or even break.