To sharpen tufting gun scissors, you can use a sharpening stone or a professional sharpening service. Sharpening tufting gun scissors is an essential task to ensure smooth and precise cuts in upholstery projects.

Dull scissors can result in uneven or frayed edges, ruining the overall look and quality of the finished product. In this guide, we will explore the best methods to sharpen tufting gun scissors, providing you with the necessary knowledge to maintain the sharpness of your tools.

With the right techniques, you can restore the cutting efficiency of your scissors and prolong their lifespan, ultimately enhancing your crafting experience. So, let’s delve into the art of sharpening tufting gun scissors and give your upholstery projects a professional touch.

Understanding Scissor Sharpening

Scissor sharpening is crucial for optimizing the performance of your tufting gun scissors. Let’s delve into the

Importance Of Sharp Scissors

.- Sharp scissors ensure precise and efficient cutting.

- Dull scissors can damage fibers and affect the quality of your work.

- Maintaining sharp scissors is essential for professional results.

When it comes to scissor sharpening, it’s essential to know the

Types Of Scissor Sharpening

.- Blade Sharpening: Involves honing the cutting edge of the scissor blades.

- Adjustment Sharpening: Involves realigning the blades for optimal cutting.

- Professional Sharpening Services: Ensure precise and expert sharpening.

Proper scissor sharpening techniques are vital for the longevity and functionality of your tufting gun scissors.

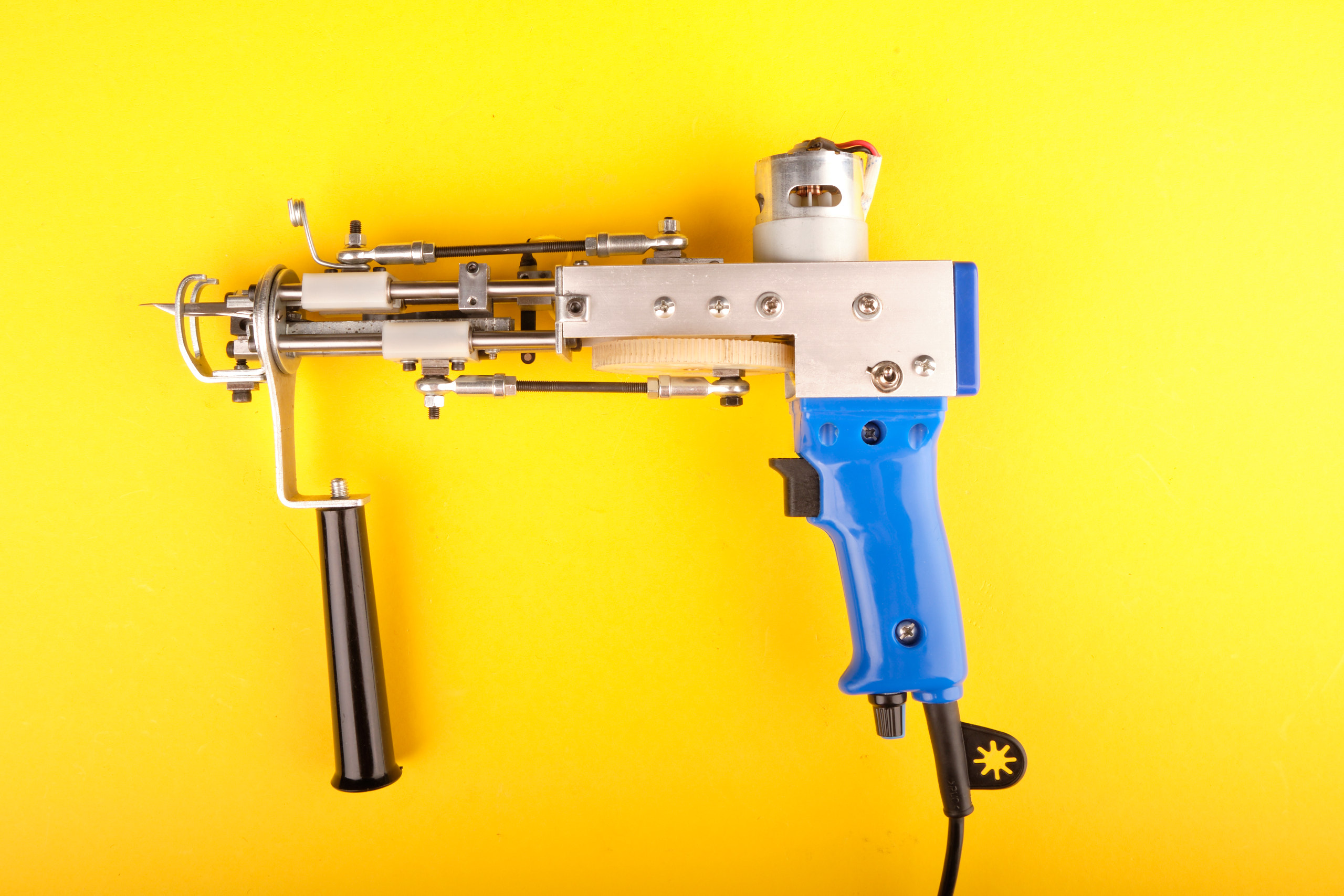

Credit: machinetufting.com

Tools And Supplies

When it comes to sharpening your tufting gun scissors, having the right tools and supplies is essential. Investing in quality tools will ensure efficient and effective sharpening, prolonging the lifespan of your scissors. Here are the must-have tools and supplies:

Quality Sharpening Stone

A quality sharpening stone is the cornerstone of properly sharpening tufting gun scissors. Look for a stone that is durable, long-lasting, and capable of providing a fine edge to your scissors. The sharpening stone should have a suitable grit for the task, typically ranging from 1000 to 3000 grit. Higher grit stones will provide a finer and sharper edge, while lower grit stones are more suitable for repairing damaged blades.

Lubricating Oil

Lubricating oil is an essential supply for maintaining the functionality and longevity of your scissors. When sharpening tufting gun scissors, applying a few drops of lubricating oil to the sharpening stone will reduce friction, prevent overheating, and ensure a smoother sharpening process. Choose a high-quality lubricating oil that is specifically designed for sharpening tools.

Preparing The Scissors

Preparing the scissors is an essential step before sharpening tufting gun scissors. By properly cleaning and inspecting the scissors, you can ensure that they are in good condition and ready to be sharpened effectively.

Cleaning The Scissors

To start the process, it’s crucial to clean the scissors thoroughly. This will remove any dirt, grime, or residue that may have built up on the blades. To clean the scissors:

- Prepare a mixture of warm water and mild soap.

- Gently soak a clean cloth in the soapy water.

- Wipe the blades of the scissors using the damp cloth, making sure to remove any dirt or debris.

- Rinse the scissors with clean water to remove any soap residue.

- Pat dry the scissors with a soft, lint-free cloth.

By following these steps, you can ensure that your scissors are clean and free from any contaminants that could interfere with the sharpening process.

Inspecting For Damage

After cleaning the scissors, it’s important to inspect them for any signs of damage. This will allow you to identify any issues that might affect the sharpening process and address them appropriately. When inspecting the scissors:

- Check the blades for nicks, chips, or any unevenness that may need repair.

- Examine the pivot screw to ensure it is tight and functioning properly.

- Inspect the handle for any cracks or signs of wear.

- If you notice any damage, consider contacting a professional to repair the scissors before attempting to sharpen them.

By thoroughly cleaning and inspecting your scissors, you can ensure that they are in optimal condition for sharpening. This will help you achieve the best results and extend the lifespan of your tufting gun scissors.

Sharpening Process

Keep your tufting gun scissors sharp by following these simple steps for the sharpening process. First, ensure the blade is clean and dry. Use a sharpening stone or honing steel to gently sharpen the blade at a 20-degree angle. Test the sharpness by cutting paper or fabric.

Repeat the process as needed for a pristine cutting edge.

Proper Angle For Sharpening

Achieving the correct angle when sharpening the scissors is vital.

Maintain a steady hand and ensure the angle is consistent throughout the process.

Maintaining Consistent Pressure

Consistent pressure is key to sharpening effectively.

Apply even pressure along the blade while sharpening for best results.

To sharpen tufting gun scissors, focus on the blade’s edge.

Using a sharpening stone, gently run the scissors along the edge to remove any dullness.

Verify the angle is correct and maintain steady pressure for optimal sharpness.

Test the scissors on fabric to ensure they are sharp enough for tufting work.

Testing And Final Touches

To sharpen tufting gun scissors, use a sharpening stone at a 30-45 degree angle. Prioritize firm, consistent strokes for best results. After sharpening, perform a final touch by wiping the blades with a clean cloth to remove any metal filings.

Testing and Final Touches Once you have sharpened the tufting gun scissors, it’s essential to perform a few checks to ensure they are in optimal condition. The testing phase allows you to confirm the sharpness of the scissors and ensure they are ready for use. Additionally, applying lubricating oil will prolong their lifespan and enhance their performance. Checking Sharpness To check the sharpness of the tufting scissors, carefully run the blade against a piece of fabric. Observe the cutting motion to ensure the scissors glide smoothly through the fabric without snagging or tearing. If there is any resistance or uneven cutting, it may indicate that further sharpening is required. Applying Lubricating Oil After confirming the sharpness, it’s crucial to apply lubricating oil to the scissors. Use a small amount of oil and apply it to the pivot point and along the blades. This will help reduce friction and prevent rusting, ensuring the scissors remain in top condition for an extended period. With these final touches, your tufting gun scissors should be ready to use, providing precise and efficient cutting for your tufting projects.Credit: www.tuftipedia.com

Credit: machinetufting.com

Frequently Asked Questions On How To Sharpen Tufting Gun Scissors

How Often Should I Sharpen Tufting Gun Scissors?

You should sharpen tufting gun scissors every 3-6 months, depending on usage. Regular sharpening ensures optimal cutting performance and prevents fabric damage.

What Are The Signs That Tufting Gun Scissors Need Sharpening?

Signs of blunt tufting gun scissors include fraying fabric edges, increased effort required for cutting, and uneven cuts. Sharpen if you notice these.

Can I Sharpen Tufting Gun Scissors At Home?

Yes, with proper tools and techniques, you can sharpen tufting gun scissors at home. However, if you’re unsure, seek professional sharpening services for best results.

Conclusion

Ensuring your tufting gun scissors are sharp is crucial for achieving precise results. By following the steps outlined in this blog post, you can easily maintain and sharpen your scissors at home. Remember, a well-maintained tool is essential for successful tufting gun projects.

Keep creating with sharp scissors!