To sharpen bolt cutters, first, place the cutter blades in a vise grip and use a metal file to file the blades at a 45-degree angle. Then, file along the entire cutting edge to remove any burrs or nicks.

A smooth, clean cutting edge is necessary for optimal cutting performance. Bolt cutters are a valuable tool for cutting through thick materials, such as chains and padlocks. Over time, the cutting blades can become dull or damaged, leading to reduced cutting efficiency.

Thankfully, with a few simple steps, you can sharpen your bolt cutters and restore their cutting edge. We will guide you on how to sharpen bolt cutters effectively, ensuring they stay sharp and capable of tackling tough cutting tasks.

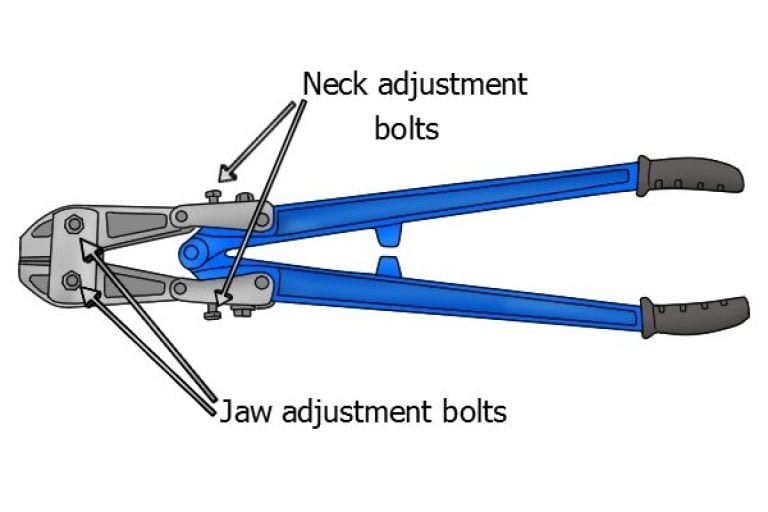

Credit: techteamproducts.com

Choosing The Right Bolt Cutter

When selecting a bolt cutter, it’s crucial to choose the right one to ensure efficiency and effectiveness in your cutting tasks.

Consider The Material

Bolt cutters are designed for various materials, so consider the material you’ll be cutting to select the appropriate tool.

Selecting The Size

Ensure you choose the right size bolt cutter by considering the thickness of the materials you’ll commonly cut.

Credit: www.wonkeedonkeetools.co.uk

Gathering The Necessary Tools

When it comes to sharpening bolt cutters, having the right tools is essential. Gathering the necessary tools not only ensures a smooth and efficient sharpening process but also helps maintain the longevity of your bolt cutters. Before you begin, it is important to inspect the blades and prepare your work area properly.

Inspecting The Blades

Before sharpening your bolt cutters, it is crucial to inspect the blades for any signs of damage or wear. Damaged blades can affect the cutting performance and may require further repair. To inspect the blades, follow these steps:

- Ensure the bolt cutters are in the closed position.

- Inspect the blade edges for any nicks, chips, or dull spots.

- Check for any rust or corrosion on the blades.

- If you notice any significant damage or corrosion, it is recommended to seek professional assistance or replace the blades if necessary.

Preparing The Work Area

Preparing a suitable work area is essential for a safe and effective sharpening process. Here are a few steps to help you prepare your work area:

- Select a well-lit and properly ventilated area to work in.

- Cover your work surface with a protective layer to prevent any damages or scratches.

- Gather a clean cloth or towel to wipe away any debris or excess lubricant.

- Keep a container or tray nearby to collect any metal shavings or debris.

- Ensure you have the necessary lubricant or sharpening solution to use during the sharpening process.

Step-by-step Sharpening Process

Learn the step-by-step sharpening process for bolt cutters. Begin by cleaning the blades and lubricating the mechanism. Use a sharpening tool to grind the cutting edges evenly. Test the sharpness with a piece of metal before putting them back to use.

Cleaning The Blades

Before you begin sharpening your bolt cutters, it is important to clean the blades thoroughly to remove any dirt, debris, or rust that may have accumulated. This will ensure that you can accurately assess the condition of the cutting edges and achieve the best possible sharpening results.

To clean the blades, follow these simple steps:

- Wipe the blades with a clean cloth to remove any loose dirt or debris.

- Apply a rust dissolving solution, such as WD-40, to any rusted areas on the blades.

- Gently scrub the blades with a wire brush or steel wool to remove the rust.

- Rinse the blades with water and dry them thoroughly with a clean cloth.

Once the blades are clean, you can move on to the next step in the sharpening process.

Sharpening The Cutting Edges

To ensure that your bolt cutters are ready to tackle any cutting task effectively, it is essential to sharpen the cutting edges properly. Here is a step-by-step guide to help you sharpen your bolt cutters:

- Secure the bolt cutters in a vise or clamp to prevent them from moving while sharpening.

- Inspect the cutting edges to identify any nicks, dull spots, or unevenness.

- Using a flat file or sharpening stone, start at one end of the cutting edge and work your way towards the other end.

- Hold the file or sharpening stone at a slight angle against the cutting edge and apply firm but gentle pressure.

- Move the file or sharpening stone in a sweeping motion along the cutting edge, maintaining the same angle and pressure.

- Repeat this process several times until you achieve a sharp and even cutting edge.

Make sure to continuously check the sharpness of the cutting edges as you sharpen, and adjust your technique if necessary.

Once you are satisfied with the sharpness of your bolt cutter’s cutting edges, remove them from the vise or clamp and wipe away any metal shavings.

Now that you have successfully completed the step-by-step sharpening process, your bolt cutters are ready to deliver precise and efficient cutting performance in your future tasks.

Testing And Maintenance

Bolt cutters are essential tools for various applications, ensuring they’re sharp and well-maintained is crucial. Regular testing and maintenance help optimize their performance and durability.

Testing The Sharpness

- Inspect the blades for any visible nicks or dullness.

- Try cutting through a piece of soft material to test sharpness.

- If the cut is clean and effortless, the blades are sharp.

- For a more precise test, try cutting through a harder material.

Regular Maintenance Tips

- After use, wipe the blades clean to remove any debris or residue.

- Apply a thin layer of lubricant to prevent rust and ensure smooth cutting.

- Check the pivot point and adjust if blades are misaligned.

- Store bolt cutters in a dry place to prevent corrosion.

Safety Precautions

Bolt cutters are powerful tools that require proper safety precautions to ensure accidental injury is prevented. When it comes to sharpening bolt cutters, following safety measures is crucial to protect yourself and others who may handle the equipment. Here are essential safety precautions to observe:

Wearing Protective Gear

Wearing appropriate protective gear when sharpening bolt cutters is essential to ensure your safety. This includes safety goggles to shield your eyes from metal particles or debris, heavy-duty gloves to protect your hands, and ear protection to prevent damage from loud noises.

Proper Handling And Storage

Proper handling and storage of bolt cutters play a significant role in preventing accidents. Always handle the tool with care, avoiding sharp edges and keeping it away from the reach of children. When not in use, securely store the bolt cutters in a designated area, out of the way of foot traffic.

Credit: m.youtube.com

Frequently Asked Questions For How To Sharpen Bolt Cutters

Can You Sharpen Bolt Cutter Blades?

Yes, bolt cutter blades can be sharpened by using a file or a sharpening stone.

How Can I Make My Bolt Cutter Cut Better?

To improve the cutting performance of your bolt cutter, try these tips: 1. Use a lubricant on the blades for smoother cutting. 2. Adjust the pivot point to ensure proper alignment. 3. Sharpen the blades regularly with the right tools.

4. Apply steady pressure while cutting to avoid blade damage. 5. Choose a quality bolt cutter with the appropriate size for the task at hand.

Can You Sharpen Bolt Cutters With A File?

Yes, you can sharpen bolt cutters with a file. Simply run the file along the blade edges to remove any dull spots and restore their cutting ability. Regular maintenance and sharpening can help extend the lifespan and efficiency of your bolt cutters.

How Do You Sharpen Cutters?

To sharpen cutters, use a sharpening tool or file to sharpen the edge evenly. Hold the cutter at the correct angle and apply even pressure while sharpening. Regular maintenance will keep your cutters sharp for efficient cutting.

Conclusion

By following these simple steps, you can effectively sharpen your bolt cutters at home. Remember to prioritize safety and regularly maintain your tools for optimal performance. Stay equipped with a sharp pair of bolt cutters to tackle any task effortlessly.

Start sharpening and enhancing your cutting efficiency today.