Electronic Gas Detectors: Ensuring Safety with Advanced Technology

Electronic gas detectors are devices designed to detect the presence of harmful gases in the environment. These detectors utilize advanced technology to provide accurate and real-time readings, ensuring the safety of individuals and preventing potential hazards.

With their compact size and easy-to-use features, electronic gas detectors have become an essential tool in various industries such as manufacturing, construction, and mining. By continuously monitoring the air quality, these detectors help to identify and contain gas leaks, allowing prompt action to be taken to protect lives and property.

Whether it’s detecting toxic gases or explosive levels of combustible gases, electronic gas detectors play a crucial role in maintaining a safe working environment and minimizing the risk of accidents.

The Importance Of Advanced Technology In Gas Detection

Gas detection is crucial in ensuring safety, and advanced technology is revolutionizing the field. Electronic gas detectors offer accurate and reliable results, providing real-time information to prevent potential hazards and protect lives.

Advanced Technology Revolutionizing Gas Detection:

Today, the safety measures and protocols surrounding gas detection have evolved significantly, thanks to the advancements in technology. Electronic gas detectors have taken center stage in the field, bringing forth a new era of efficiency and accuracy. These innovative devices utilize advanced technology to detect and monitor the presence of harmful gases in various environments.

With cutting-edge features and functionalities, electronic gas detectors are revolutionizing the way we approach gas detection, ensuring enhanced safety for individuals working in potentially hazardous settings.

- Integration of sensors and microprocessors: Electronic gas detectors are equipped with highly sensitive sensors that can quickly and accurately detect even the smallest traces of hazardous gases. These sensors are seamlessly integrated with microprocessors, enabling real-time data analysis and instant alerts when gas levels reach critical points.

- Wireless connectivity and remote monitoring: The incorporation of wireless technology has further revolutionized gas detection systems. With wireless connectivity capabilities, electronic gas detectors can transmit data to central monitoring systems. This allows for remote monitoring and ensures that personnel responsible for safety can monitor gas levels in real-time from a safe distance.

- Data logging and analysis: Advanced electronic gas detectors have the ability to log and store data, providing a comprehensive record of gas levels over time. This data can be later analyzed to identify trends, track potential risks, and enhance safety protocols. Such data-driven insights empower safety professionals to make informed decisions and take proactive measures to mitigate potential hazards.

- User-friendly interfaces and visual indicators: Electronic gas detectors are designed with user-friendly interfaces and visual indicators to ensure ease of use. These interfaces provide clear and concise information about gas levels, alarms, calibration status, and other essential data. Visual indicators, such as LED lights or LCD screens, offer instant visibility and quick interpretation of crucial information, leaving no room for confusion or misinterpretation.

- Continuous monitoring and real-time alerts: One of the significant advantages of advanced electronic gas detectors is their ability to provide continuous monitoring and real-time alerts. This means that gas levels are monitored constantly, ensuring timely detection of any gas leaks or hazardous situations. In the event of a potential threat, the detectors promptly generate audible and visible alarms, alerting individuals to take immediate action.

- Enhanced portability and durability: Electronic gas detectors have become increasingly portable and durable, making them highly versatile in various industries and environments. Modern devices are compact and lightweight, allowing for easy carrying and deployment wherever required. Additionally, they are built to withstand challenging conditions, including extreme temperatures, humidity, and vibrations, ensuring reliable performance even in demanding settings.

:

As the demand for enhanced safety and risk management persists, the role of advanced technology in gas detection becomes increasingly crucial. The integration of cutting-edge features and functionalities in electronic gas detectors has transformed the way we approach gas safety, ensuring improved accuracy, reliability, and efficiency.

By leveraging these advancements, industries can safeguard their workforce, prevent accidents, and create a safer working environment for all. Embracing advanced technology in gas detection is not only a compliance requirement but also a necessary step towards enhancing safety protocols and protecting lives.

How Electronic Gas Detectors Work

Electronic gas detectors function by utilizing sensors to detect and measure gases in the surrounding environment. These detectors can accurately identify and alert users to the presence of harmful gases, enabling prompt action to ensure safety.

Sensors And Detection Mechanisms:

- Electronic gas detectors use sensors to detect the presence of various gases in the environment.

- Different types of sensors are used, depending on the specific gas being monitored. These sensors include electrochemical sensors, catalytic bead sensors, infrared sensors, and semiconductor sensors.

- Electrochemical sensors work by measuring the electrical current produced when a target gas reacts with an electrode. This reaction generates a signal that is proportional to the gas concentration.

- Catalytic bead sensors, on the other hand, use a heated wire coated with a catalyst to promote the combustion of gases. This combustion generates heat, which changes the wire’s resistance and indicates the gas concentration.

- Infrared sensors detect gases based on their ability to absorb certain wavelengths of infrared light. By measuring the amount of light absorbed, the sensor can determine the gas concentration.

- Semiconductor sensors utilize a silicon chip with a sensing element capable of reacting with specific gases. When the target gas interacts with the sensing element, it alters the electrical conductivity of the chip, providing a measurement of the gas concentration.

Real-Time Monitoring And Data Analysis:

- Electronic gas detectors offer real-time monitoring capabilities, allowing for continuous gas detection and measurement.

- These detectors collect data from the sensors and analyze it to determine the gas concentration in the environment.

- The collected data is then processed and displayed on a screen or interface, providing instant feedback to the user.

- Real-time monitoring enables immediate action to be taken in case of gas leaks or unsafe conditions.

- Data analysis features include setting alarm thresholds, which trigger an alert when gas concentrations exceed safe levels.

- Historical data can be recorded and analyzed to identify patterns, trends, or potential risks over time.

- This data can be used for proactive maintenance, to optimize safety protocols, and to ensure compliance with regulations.

- Electronic gas detectors can also be connected to a network, enabling remote monitoring and centralized data management.

Electronic gas detectors utilize various sensors and detection mechanisms to provide accurate and real-time monitoring of gas concentrations. The data collected enables prompt action, ensuring safety and compliance in various environments.

Key Features Of Electronic Gas Detectors

The key features of electronic gas detectors include advanced sensors for accurate gas detection, easy-to-read LCD displays, audible and visual alarms, compact designs for portability, and long battery life for extended use. These detectors are essential for ensuring safety in various industries, such as oil and gas, mining, and manufacturing.

Accuracy And Reliability:

- Electronic gas detectors are known for their exceptional accuracy and reliability in detecting and measuring gas levels. These devices use advanced technology to ensure precise readings, providing users with accurate information about the concentration of gases in the surrounding environment.

- By utilizing sensors and sophisticated algorithms, electronic gas detectors can detect even the slightest traces of gases, making them highly reliable in identifying potential risks and hazards.

- The accuracy of electronic gas detectors is crucial in industries where the presence of certain gases could be life-threatening or cause damage to equipment. With their reliable performance, these detectors offer peace of mind and enable prompt action to be taken to mitigate any potential dangers.

Alarm Systems And Notifications:

- One of the key features of electronic gas detectors is their alarm systems and notifications. These devices are equipped with audible and visual alarms that are triggered when gas levels exceed preset thresholds.

- When the detectors detect the presence of hazardous gases, they emit loud alarms and flash bright lights, alerting users to the potential danger. This immediate notification is essential for prompt evacuation or for taking appropriate measures to ensure safety.

- Electronic gas detectors also come with different alarm indicators to provide additional information to users. Some detectors may have different alarm tones or patterns to differentiate between different gas types. This feature helps users to quickly identify the specific gas present, enhancing response time and effectiveness.

User-Friendly Interfaces:

- Electronic gas detectors are designed with user-friendly interfaces to make operation and readings easy to understand for all users, regardless of their level of expertise. These devices often come with intuitive buttons and display screens that provide clear and concise information.

- The interfaces of these detectors are typically designed to be simple and straightforward, allowing users to navigate through various settings and options effortlessly. The display screens often show gas concentration levels, battery life, and other relevant information in a user-friendly format.

- Some electronic gas detectors also offer additional features such as data logging and graphing capabilities, providing users with a convenient way to track and analyze gas concentration trends over time. These user-friendly interfaces make it easier for individuals to monitor gas levels effectively and make informed decisions accordingly.

Fixed Gas Detectors

Fixed gas detectors are electronic devices designed to detect the presence of hazardous gases in an area. These detectors offer reliable and continuous monitoring, ensuring the safety of workers and preventing potential accidents.

Electronic Gas Detectors:

With the increasing importance of safety in various industries, electronic gas detectors have become essential tools for monitoring and detecting harmful gases in the workplace. Fixed gas detectors, in particular, are designed to continuously monitor specific areas for the presence of potentially dangerous gases.

In this section, we will explore the applications and benefits of fixed gas detectors, as well as important considerations for their installation and maintenance.

Applications And Benefits:

- Industrial Settings: Fixed gas detectors find extensive use in industrial settings such as refineries, chemical plants, and manufacturing facilities. These detectors help ensure the safety of workers by providing early warning of gas leaks or abnormal levels of hazardous gases.

- Laboratories: Laboratories dealing with volatile substances and gases rely on fixed gas detectors to protect researchers and prevent accidents. These detectors provide real-time monitoring, enabling prompt response to any concerning gas levels.

- Underground Mines: In the mining industry, fixed gas detectors are crucial for detecting and monitoring gases like methane or carbon monoxide, which are common in underground environments. These detectors play a crucial role in preventing explosions and providing miners with a safe working environment.

Installation And Maintenance Considerations:

- Proper Location: Installing fixed gas detectors at strategic locations within a facility is essential for accurate gas detection. Consider factors such as gas dispersion patterns, ventilation systems, potential leak sources, and areas where gases are likely to accumulate.

- Regular Calibration: To ensure reliable performance, fixed gas detectors should undergo periodic calibration. This process involves adjusting the device to a known concentration of gas, thereby ensuring accurate readings.

- Routine Maintenance: Regular maintenance is vital to keep fixed gas detectors in optimal condition. This includes cleaning the detectors, replacing any worn-out parts, and verifying the functionality of alarms and sensors.

- Training and Education: Proper training of personnel responsible for the operation, maintenance, and response to fixed gas detectors is crucial. It equips them with the necessary knowledge to interpret gas levels accurately and take appropriate actions in case of an emergency.

- Compliance with Regulations: It is essential to adhere to applicable health and safety regulations and industry standards when installing and maintaining fixed gas detectors. This helps ensure compliance and the overall effectiveness of the gas detection system.

Ensure the safety of your workplace and minimize the risk of gas-related incidents by implementing reliable fixed gas detectors. By accurately and continuously monitoring gas levels, these detectors provide crucial early warnings that allow for prompt response and prevention of potential disasters.

Remember to consider the specific applications and benefits of fixed gas detectors, as well as the important installation and maintenance considerations when implementing them in your facility.

Remember, safety should always be a top priority, and investing in the right gas detection system is a critical step towards creating a secure working environment.

***

Portable Gas Detectors

Portable gas detectors are electronic devices that help to detect the presence of hazardous gases in various environments. These detectors are designed to be compact and easy to carry, making them convenient for on-the-go gas detection. With their advanced technology, they provide accurate and reliable results, ensuring the safety of workers and the general public.

Advantages For Various Industries

Portable gas detectors are an essential tool used in various industries to ensure safety and prevent potential hazards. These compact devices are designed to detect and measure the levels of harmful gases in the surrounding environment. Whether you work in the oil and gas, mining, chemical, or manufacturing industry, having a reliable portable gas detector can offer several advantages:

- Early gas detection: Portable gas detectors enable the early detection of potentially hazardous gases, allowing workers to take immediate action and prevent accidents or exposure to toxic substances.

- Increased safety: By continuously monitoring the air quality, portable gas detectors provide a safeguard against unseen dangers, reducing the risk of explosions, fires, or health-related issues caused by gas leaks.

- Versatility: These detectors are designed to detect a wide range of gases, including flammable gases, toxic gases, and oxygen levels. This versatility makes them suitable for various industries where different gas hazards may be present.

- Real-time monitoring: Portable gas detectors offer real-time data, allowing workers to monitor gas levels constantly. This feature is particularly beneficial for industries where gas concentrations can fluctuate.

- Portable and easy to use: As the name suggests, portable gas detectors are lightweight and compact, making them convenient for workers to carry around. They are also designed with user-friendly interfaces, ensuring easy operation and quick response in critical situations.

- Cost-effective: Investing in portable gas detectors can save money in the long run by preventing accidents, reducing downtime, and minimizing the potential for costly repairs or compensation claims.

Factors To Consider When Choosing A Portable Detector

When selecting a portable gas detector for your industry, it is crucial to consider several key factors to ensure the device meets your specific needs. Here are some important considerations:

- Gas detection requirements: Understand the specific gases that are present in your workplace environment. Different detectors are designed to detect different gases, so ensure the detector you choose is capable of monitoring the relevant gases in your industry.

- Sensor type and technology: Different gas detectors use various sensor types, including electrochemical, infrared, or catalytic bead sensors. Research and compare the advantages of each sensor technology to determine the most suitable one for your industry’s gas detection requirements.

- Alarm system: Look for a portable gas detector that offers an effective alarm system. Audible, visual, and vibrating alarms are crucial for alerting workers of potential gas hazards, especially in noisy or high-risk environments.

- Battery life and durability: Consider the battery life of the detector and ensure it can operate for a sufficient duration before requiring recharging or battery replacement. Additionally, choose a robust and durable device that can withstand the conditions of your industry.

- Calibration and maintenance: Regular calibration and maintenance are essential for accurate gas detection. Ensure the detector you choose has a user-friendly calibration process and consider the availability of calibration gases and maintenance support.

- Data logging and connectivity: Some portable gas detectors offer data logging capabilities, allowing you to track and analyze gas levels over time. Consider if this feature is important for your industry. Additionally, connectivity options such as Bluetooth or USB can simplify data transfer and analysis.

Taking these factors into account when choosing a portable gas detector will help ensure optimal safety and efficiency in your industry. Selecting the right detector can contribute to maintaining a secure work environment, protecting workers from potential gas-related risks, and promoting overall productivity.

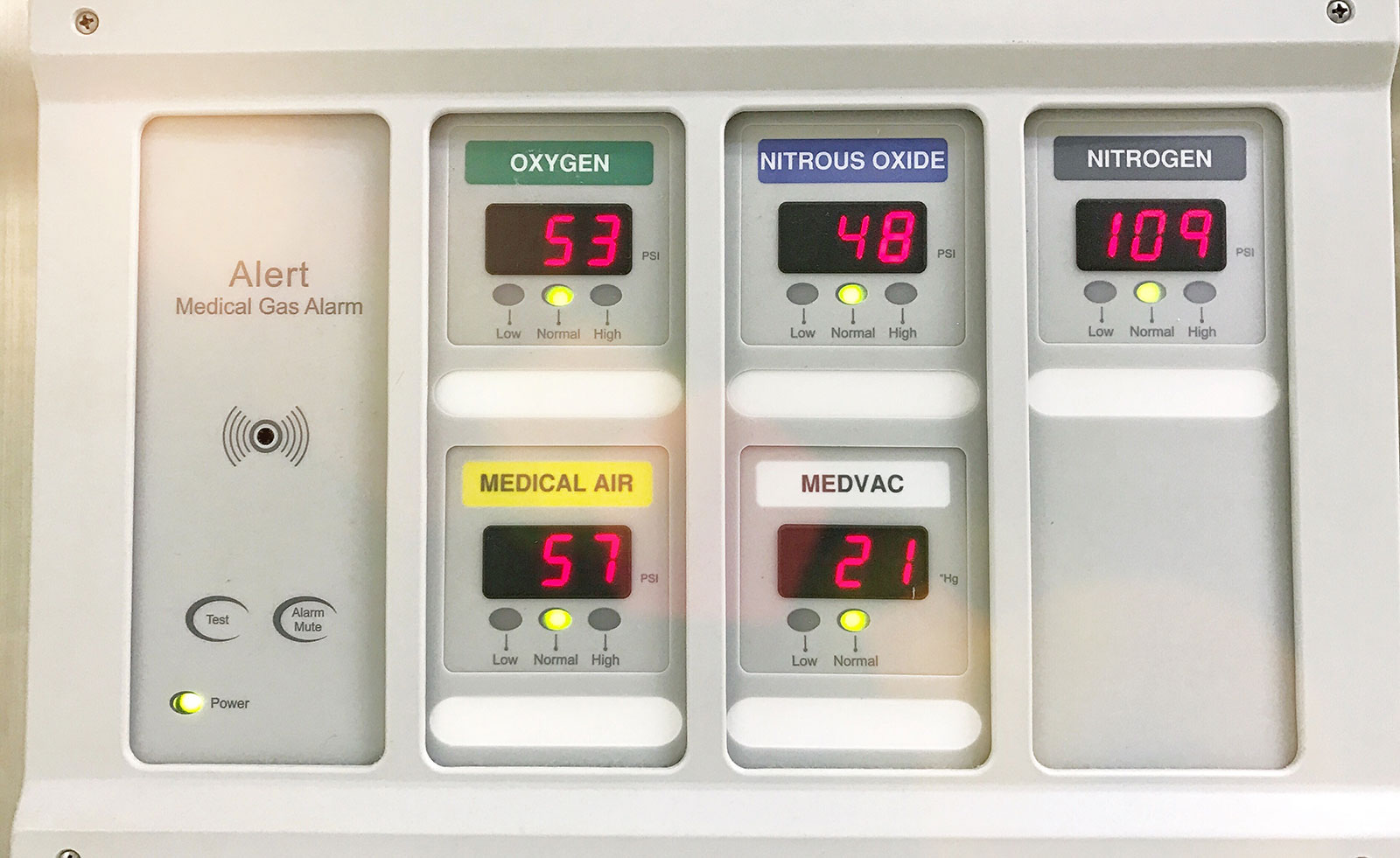

Credit: www.apsf.org

Wireless Gas Detectors

Wireless gas detectors provide an efficient solution for detecting electronic gases. They offer reliable and continuous monitoring, alerting users to potential dangers in real-time. These detectors are easy to install and operate, ensuring safety in various industries.

Electronic gas detectors are essential devices used to monitor the presence of hazardous gases in various industries. With advancing technology, wireless gas detectors have emerged as a game-changer in the field of gas detection. These detectors utilize wireless technology to provide real-time information about gas levels, improving safety measures in the workplace.

In this section, we will explore the benefits of wireless technology in gas detection, focusing on its integration with existing systems.

Benefits Of Wireless Technology In Gas Detection:

- Enhanced flexibility: Wireless gas detectors offer the advantage of flexibility as they can be easily installed in any location without the need for extensive wiring. This allows for easy repositioning of the detectors as per changing requirements.

- Remote monitoring: The wireless nature of these detectors enables remote monitoring of gas levels. With the help of a centralized monitoring system, users can keep track of gas concentrations in real-time, ensuring prompt responses to any hazardous situations.

- Cost-effective installation: Unlike traditional gas detectors, wireless gas detectors eliminate the need for extensive and costly wiring installations. This not only reduces installation time but also cuts down on the overall expenses.

- Integration with existing systems: One of the significant advantages of wireless gas detectors is their seamless integration with existing systems. They can be easily integrated with other safety devices and control systems, allowing for a comprehensive safety network within the facility.

- Easy maintenance and scalability: Wireless gas detectors simplify maintenance procedures by providing intuitive user interfaces and software platforms. Additionally, these detectors can be easily expanded or modified as per changing requirements, making them highly scalable for future needs.

Wireless gas detectors provide numerous benefits in terms of flexibility, remote monitoring, cost-effectiveness, integration, and scalability. Their advanced wireless technology offers a reliable and efficient solution for gas detection, ensuring a safer working environment. So, it’s no surprise that these detectors are gaining popularity across industries.

Infrared Gas Detectors

With their advanced electronic technology, infrared gas detectors provide efficient and reliable detection of gas leaks. These devices play a crucial role in ensuring safety in various industrial settings.

Infrared gas detectors are an essential tool in many industries for detecting the presence of various gases. These detectors operate on the principle of infrared absorption, making them highly effective in detecting a wide range of gases. They are widely used in applications where there is a need to monitor toxic or flammable gases.

In this section, we will explore the principle of operation and the applications and advantages of infrared gas detectors.

Principle Of Operation:

- Infrared gas detectors work by measuring the absorption of infrared radiation by the target gas.

- They consist of a source of infrared radiation, an optical sensor, and a signal processor.

- The infrared radiation emitted by the source passes through the gas sample.

- If the gas molecules absorb some of the radiation, the intensity of the radiation reaching the sensor will be reduced.

- The sensor detects this reduction and sends a signal to the processor to indicate the presence of the gas.

Applications And Advantages:

- Infrared gas detectors are commonly used in industrial settings to monitor the levels of combustible gases such as methane, propane, and hydrogen.

- They are also used in the oil and gas industry for detecting hydrocarbons and other volatile organic compounds.

- Infrared gas detectors find applications in environmental monitoring to detect pollutants and greenhouse gases.

- They are essential in the mining industry to detect the presence of toxic gases like carbon monoxide and hydrogen sulfide.

- Infrared gas detectors offer several advantages, including:

- High sensitivity and accuracy in detecting a wide range of gases.

- Fast response time, allowing for quick detection and response to gas leaks or releases.

- Low-power consumption, making them cost-effective and ideal for continuous monitoring applications.

- They are unaffected by oxygen levels, humidity, or changes in temperature.

- Infrared gas detectors are suitable for both indoor and outdoor installations.

Infrared gas detectors operate based on the principle of infrared absorption and find extensive usage in various industries for detecting gases. They offer several advantages, including high sensitivity, fast response time, and low power consumption. Their versatility and reliability make them a valuable tool in ensuring safety and monitoring gas levels in different environments.

Photoionization Detectors

Photoionization detectors are electronic gas detectors used to monitor the presence of hazardous gases in various settings. They are highly sensitive and provide accurate and reliable detection, making them essential for ensuring safety in industries such as oil and gas, mining, and manufacturing.

Photoionization Detectors (PIDs) are a type of electronic gas detectors primarily used for detecting volatile organic compounds (VOCs) and other hazardous gases in various industries. These detectors utilize the ionization process to detect and measure the concentration of gases present in the environment.

Here’s a closer look at the ionization process and detection mechanisms used by PIDs, as well as their use cases and benefits:

Ionization Process And Detection Mechanisms:

- Photon Absorption: When a photon of sufficient energy is absorbed by a gas molecule, it can ionize the molecule by removing an electron. This process is known as ionization. PIDs employ a high-energy ultraviolet (UV) lamp that emits photons capable of ionizing gas molecules upon absorption.

- Ion Formation: As the gas molecules absorb photons, electrons within the molecules are excited and gain enough energy to break free, resulting in the formation of positive ions and free electrons in the gas sample.

- Ion Drift: Under the influence of an electric field, the positive ions and free electrons move towards their respective electrodes. The rate of ion drift is proportional to the concentration of the gas being detected.

- Current Measurement: The PID measures the resulting ion current produced by the collection of positive ions at the cathode. This current is directly proportional to the gas concentration in the environment.

Use Cases And Benefits:

- Occupational Health and Safety: PIDs are commonly used in industries such as manufacturing, oil and gas, and chemical plants to monitor and ensure worker safety by detecting the presence of hazardous gases and VOCs.

- Environmental Monitoring: These detectors play a vital role in environmental monitoring programs by enabling the measurement of pollutants and harmful gases in outdoor and indoor environments.

- Leak Detection: PIDs are effective tools for identifying leaks in gas pipelines, storage tanks, and other industrial equipment, allowing for prompt repairs and preventing potential accidents.

- Hazmat Response: Emergency responders and hazmat teams utilize PIDs to swiftly identify hazardous substances at accident sites and mitigate risks to public safety.

- Indoor Air Quality: PIDs can help in assessing indoor air quality by detecting potentially harmful gases emitted from building materials, furniture, cleaning products, and other sources.

- Real-time Monitoring: PIDs provide real-time gas concentration readings, allowing for immediate response in case of exceeding safety thresholds.

- Portability and Ease of Use: These detectors are often compact and lightweight, making them convenient for field applications. They are also user-friendly, with simple operation and quick response times.

- Wide Gas Sensitivity Range: PIDs can detect a broad range of gases, including volatile organic compounds, toxic gases, combustible gases, and certain inorganic compounds, making them versatile for various gas detection needs.

Photoionization detectors utilize the ionization process and detection mechanisms to measure the concentration of gases, particularly volatile organic compounds. Their applications span occupational safety, environmental monitoring, leak detection, hazmat response, indoor air quality assessment, and more. With their portability, ease of use, and ability to detect a wide range of gases, PIDs are valuable tools for ensuring safety in diverse industries.

Electrochemical Sensors

Electrochemical sensors are essential components in electronic gas detectors, providing accurate and reliable detection of various gases by converting chemical reactions into electrical signals. These sensors play a crucial role in ensuring safety and protecting lives in industries and environments where gas detection is critical.

Chemical Reactions And Gas Detection

Gas detection using electrochemical sensors relies on the principles of chemical reactions to accurately measure the presence of certain gases. These sensors employ a specialized chemical electrode that interacts with the target gas, initiating a reaction that generates an electrical signal proportional to the concentration of the gas.

This electrical signal is then converted into a measurable reading, allowing for effective gas detection. Here are some key points to consider:

- Electrochemical sensors utilize specific chemicals that selectively react with target gases, ensuring accurate and reliable detection.

- These sensors are highly sensitive, capable of detecting even low concentrations of gases, making them suitable for various applications, including industrial environments and household safety.

- They offer excellent response times, quickly alerting users to unsafe gas levels or potential leaks.

- Electrochemical sensors are capable of accurately measuring gases such as carbon monoxide, hydrogen sulfide, oxygen, and many more.

- The sensors can be customized to target specific gases, providing flexibility in gas detection applications.

Pros And Cons Compared To Other Technologies:

When comparing electrochemical sensors to other gas detection technologies, they offer distinct advantages and disadvantages. Let’s explore them further:

Pros:

- Highly sensitive and capable of detecting low gas concentrations, ensuring accurate measurements.

- Fast response times enable quick detection and timely alerts.

- Can be customized for specific gases, allowing for targeted gas detection.

- Wide availability and range of gas detection options using electrochemical sensors.

- Relatively low cost compared to some alternative technologies.

Cons:

- Limited lifespan due to the reactive chemicals used, requiring periodic sensor replacement.

- Vulnerable to interference from other chemicals, which may affect accuracy.

- Possibility of sensor poisoning or degradation over time, leading to reduced performance.

- Some electrochemical sensors may require regular calibration to maintain accuracy.

- Performance can be affected by environmental factors such as temperature and humidity.

Electrochemical sensors play a crucial role in gas detection by utilizing chemical reactions to accurately measure the presence of gases. While they offer high sensitivity, fast response times, and customization options, considerations should be given to their limited lifespan, susceptibility to interference, and potential performance degradation.

Proper Placement And Installation

Proper placement and installation of electronic gas detectors is crucial for effective monitoring and prevention of gas leaks. Ensuring these devices are strategically positioned and correctly installed greatly enhances safety in residential, commercial, and industrial environments.

Electronic Gas Detectors:

Electronic gas detectors are essential safety devices designed to detect and alert individuals to the presence of potentially harmful gases in various settings. However, for these detectors to function effectively, proper placement and installation are crucial. Understanding gas behavior and dispersion, as well as adhering to regulations and guidelines, ensures the accuracy and reliability of these life-saving devices.

In this section, we will explore the importance of proper placement and installation of electronic gas detectors.

Understanding Gas Behavior And Dispersion:

To ensure the effective detection of harmful gases, it is vital to understand how gases behave and disperse within different environments. Here are some key points to consider:

- Different gases have varying densities, which affects their behavior in a given space. For instance, heavier gases tend to settle down low, while lighter gases may rise and disperse vertically.

- Gas dispersion is influenced by factors such as ventilation, wind direction, temperature, and airflow patterns within a specific area.

- Adequate placement of gas detectors in areas where gas leaks are more likely to occur, such as near potential leak sources or at lower levels where heavier gases tend to accumulate, can significantly enhance detection accuracy.

Regulations And Guidelines For Installation:

Proper installation of electronic gas detectors involves following specific regulations and guidelines to ensure reliable performance and compliance. Consider the following points:

- Regulatory bodies, such as OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association), provide comprehensive guidelines regarding the installation and maintenance of gas detectors in different industries and settings.

- Placement height should be carefully determined based on the specific gas being detected, its density, and the environment in which it is used. For example, hydrogen gas detectors are usually installed at higher levels due to its low density and tendency to rise.

- It is crucial to avoid placing gas detectors in areas prone to extreme temperatures, direct sunlight, or excessive humidity, as these conditions can adversely affect their performance.

- Regular calibration and testing of electronic gas detectors are necessary to ensure accurate readings and early detection of gas leaks.

By considering gas behavior and dispersion patterns and adhering to relevant regulations and guidelines, you can ensure the proper placement and installation of electronic gas detectors. This guarantees optimal and reliable gas detection, enhancing the safety of individuals in various environments such as homes, workplaces, and industrial facilities.

Regular Maintenance And Calibration

Regular maintenance and calibration of electronic gas detectors is essential to ensure accurate readings and reliable performance. By regularly checking and calibrating these detectors, businesses can effectively detect and prevent potential gas leaks, ensuring the safety of both employees and the environment.

The proper maintenance and calibration of electronic gas detectors are crucial for ensuring their accuracy and reliability. By following scheduled maintenance and calibration procedures, you can be confident that your gas detectors will continue to perform at their best, keeping you and your workplace safe.

In this section, we will explore the importance of scheduled maintenance and the recommended calibration procedures and frequency.

Importance Of Scheduled Maintenance

Maintaining your electronic gas detectors regularly is essential to ensure optimal performance and accurate readings. Here are a few reasons why scheduled maintenance is crucial:

- Preventive maintenance: Regular maintenance helps identify any potential issues before they become major problems, reducing the risk of malfunctions or false alarms.

- Longevity of equipment: Proper maintenance extends the lifespan of your gas detectors, saving you money on costly replacements.

- Safety assurance: Regularly maintained detectors provide accurate readings, ensuring that any abnormal gas levels are promptly detected, and appropriate actions are taken.

- Compliance with regulations: Many industries have specific regulations regarding gas detection equipment maintenance. Adhering to these regulations helps you remain compliant with safety standards.

Calibration Procedures And Frequency

Calibration is the process of adjusting the gas detector to a known standard to ensure accurate measurements. The frequency of calibration depends on several factors, including the type of gas detector, the manufacturer’s recommendations, and your specific workplace conditions. Here are a few important points to consider:

- Manufacturer guidelines: Refer to the manufacturer’s instructions for specific calibration procedures and recommended frequency. They are the best source of information regarding calibration requirements for their particular gas detectors.

- Environmental conditions: Extreme temperature variations, exposure to corrosive substances, or heavy dust accumulation may require more frequent calibration.

- Industry regulations: Certain industries, such as oil and gas or chemical manufacturing, may have specific calibration frequency requirements that you need to adhere to.

- Internal policies: Your organization may have its own policies regarding gas detector calibration. Ensure that you follow these guidelines as well.

Remember to always document the calibration process, including the date, calibration results, and any corrective actions taken. This documentation helps maintain a record for auditing purposes and demonstrates your commitment to safety and compliance.

By prioritizing regular maintenance and following calibration procedures as recommended, you can trust that your electronic gas detectors will provide accurate gas detection and enhance the overall safety of your workplace. Stay proactive, stay safe!

Training And Education For Users

Discover the essential training and education needed for users of electronic gas detectors. Equip yourself with the knowledge and skills to effectively operate and maintain these advanced safety devices. Stay ahead of potential gas hazards with comprehensive training programs tailored specifically for electronic gas detectors.

Electronic gas detectors play a crucial role in ensuring the safety of individuals and preventing potential hazards. However, it is essential for users to receive proper training and education to effectively utilize these devices. In this section, we will explore the importance of training and education for users of electronic gas detectors.

Ensuring Proper Usage And Interpretation Of Readings:

- Familiarize users with the basic functions and features of electronic gas detectors.

- Teach users how to properly calibrate and maintain the devices to ensure accurate readings.

- Provide guidance on interpreting gas concentration readings and understanding alarm systems.

- Demonstrate the correct usage of various sensors and their limitations.

- Train users on how to respond appropriately to different gas concentration levels.

Emergency Response Protocols:

- Educate users on the importance of having clearly defined emergency response procedures.

- Ensure users understand the significance of reporting gas leaks or high concentration readings immediately.

- Train users on evacuation procedures and the proper use of personal protective equipment (PPE).

- Emphasize the need to follow established protocols when responding to gas alarms or detecting potentially hazardous environments.

- Provide information on how to conduct thorough checks before entering confined spaces.

Proper training and education are vital for users of electronic gas detectors to ensure accurate usage, interpretation of readings, and appropriate emergency response. By equipping users with the necessary knowledge and skills, we can enhance their safety and effectively mitigate potential risks.

Oil And Gas Industry

The oil and gas industry relies on electronic gas detectors to ensure the safety of workers and prevent hazardous situations. These detectors use advanced technology to accurately monitor gas levels and provide timely warnings, allowing for efficient and effective response measures to be taken.

Electronic Gas Detectors:

With the rapid growth and expansion of the oil and gas industry, ensuring the safety of workers and preventing potential hazards has become a top priority for companies. One crucial aspect of maintaining a safe work environment is the use of electronic gas detectors.

These innovative devices play a vital role in detecting and alerting workers to the presence of harmful gases, helping to prevent accidents and protect lives.

Safety Measures In Upstream, Midstream, And Downstream Operations:

In the oil and gas industry, safety measures are implemented across various operations to mitigate potential risks. Whether it’s upstream, midstream, or downstream activities, adherence to safety protocols is crucial. Here are some key safety measures in each phase:

Upstream Operations:

- Regular inspection and maintenance of equipment and machinery to ensure proper functioning.

- Implementation of comprehensive risk assessment processes to identify potential hazards and develop appropriate mitigation strategies.

- Adequate training and education of workers to enhance their understanding of safety procedures and the use of electronic gas detectors.

- Continuous monitoring of gas levels to detect any leaks or abnormal concentrations promptly.

- Emergency response plans in place to handle unexpected situations effectively.

Midstream Operations:

- Regular inspection and maintenance of pipelines and storage facilities to minimize the risk of leaks or ruptures.

- Proper handling and transportation of gases using appropriate protective equipment.

- Implementation of strict safety protocols during transfers and storage operations.

- Regular calibration and testing of electronic gas detectors to ensure accurate readings.

- Adherence to industry standards and regulations for the safe handling of hazardous materials.

Downstream Operations:

- Rigorous inspection and maintenance of refining and processing facilities to prevent accidents.

- Strict adherence to safety guidelines during storage and transportation of finished products.

- Implementation of robust fire prevention and suppression systems.

- Regular training and drills for employees to enhance their response time in case of emergencies.

- Continuous monitoring of air quality and utilizing electronic gas detectors to detect any potential leaks or harmful gases.

Electronic gas detectors are pivotal in all stages of oil and gas operations, helping to ensure the safety of workers and the environment. Remote monitoring and control play an essential role in maintaining a safe working environment.

Remote Monitoring And Control:

- Continuous monitoring of gas levels in real-time using electronic gas detectors placed at various locations throughout the operation.

- Immediate detection of any abnormal gas concentrations, allowing for prompt action to be taken.

- Alarm systems connected to electronic gas detectors ensure that workers are alerted immediately in case of hazardous gas levels.

- Remote control capabilities enable workers to adjust settings and perform necessary actions without physically being present at the site.

- Access to data and analytics provided by electronic gas detectors assists in identifying patterns, trends, and potential risks, facilitating proactive safety measures.

The oil and gas industry continues to prioritize safety, and electronic gas detectors play a crucial role in achieving this goal. With the ability to detect hazardous gases and provide real-time monitoring, these devices are essential in safeguarding workers and preventing potentially disastrous incidents.

By implementing effective safety measures throughout upstream, midstream, and downstream operations, companies can ensure the well-being of their employees and maintain sustainable and secure production processes.

Manufacturing And Industrial Facilities

Manufacturing and industrial facilities benefit from the use of electronic gas detectors, ensuring the safety of workers and preventing potential accidents. These detectors provide reliable and accurate monitoring of gas levels, enabling prompt action to be taken if any dangers are detected.

Electronic gas detectors play a crucial role in ensuring safety and preventing hazardous incidents in manufacturing and industrial facilities. With the ability to detect harmful gases, these devices offer an efficient and reliable solution for industries working with various volatile substances.

In this section, we will explore the importance of hazardous gas detection in factories and plants, as well as compliance with safety regulations.

Hazardous Gas Detection In Factories And Plants:

- Early identification and detection of hazardous gases: Electronic gas detectors swiftly detect the presence of potentially dangerous gases in manufacturing and industrial environments. This capability allows prompt action to be taken, preventing accidents and minimizing risks to workers.

- Protection of personnel and assets: By continuously monitoring the air quality in factories and plants, gas detectors ensure the safety of employees against harmful gases such as carbon monoxide, hydrogen sulfide, and combustible gases. The timely detection of these substances helps prevent life-threatening situations and safeguards valuable equipment and infrastructure.

- Prevention of explosions and fires: In industries where flammable gases are utilized or produced, the risk of explosions and fires is a constant concern. Electronic gas detectors provide an essential layer of protection by promptly alerting personnel to any spike in the concentration of combustible gases, allowing for immediate action to prevent catastrophic incidents.

- Compliance with safety regulations: Manufacturing and industrial facilities must adhere to strict safety regulations to protect both workers and the environment. Electronic gas detectors ensure that these facilities remain in compliance by continuously monitoring gas levels, providing real-time alerts, and facilitating efficient responses to hazardous situations.

- Reduction of downtime and financial losses: Any accidents or emergencies caused by hazardous gases can result in significant downtime and financial losses for factories and plants. By proactively monitoring for gas leaks and other potential dangers, electronic gas detectors help minimize the risk of disruptions to operations, allowing businesses to maintain productivity and profitability.

Electronic gas detectors are vital tools for ensuring safety and compliance in manufacturing and industrial facilities. By quickly identifying and alerting personnel to the presence of hazardous gases, these devices protect workers, assets, and the environment, while also reducing downtime and financial losses.

Compliance with safety regulations is essential, and electronic gas detectors provide an effective solution to meet these requirements. Implementing these detectors is a proactive step toward creating a safe and secure working environment in factories and plants.

Construction And Mining Sites

Electronic gas detectors are vital for construction and mining sites, providing real-time monitoring to ensure worker safety and prevent hazardous gas leaks. These detectors offer accurate and reliable measurements, giving peace of mind to workers in high-risk environments.

Electronic Gas Detectors

Gas detection is crucial in industries like construction and mining, where workers often encounter hazardous gases in confined spaces. Electronic gas detectors provide an efficient solution for ensuring the safety of individuals working in such environments. These portable devices offer reliable and accurate detection of harmful gases, enabling proactive measures to be taken in order to prevent accidents and protect lives.

Detection Of Harmful Gases In Confined Spaces

- Carbon Monoxide (CO): A silent killer, carbon monoxide is a colorless and odorless gas produced by the incomplete combustion of fuels like gasoline, natural gas, and coal. It can accumulate in confined spaces, posing significant health risks. Electronic gas detectors can detect even low levels of CO, providing early warning to workers.

- Hydrogen Sulfide (H2S): Commonly found in industries such as mining, wastewater treatment, and oil refining, hydrogen sulfide is a highly toxic gas with a distinctive odor of rotten eggs. Exposure to high levels of H2S can be deadly. Electronic gas detectors equipped with H2S sensors can quickly identify the presence of this gas, allowing workers to take necessary precautions.

- Flammable Gases: Flammable gases like methane and propane are frequently encountered in construction and mining sites. These gases can easily ignite or cause explosions if exposed to a spark or flame. Electronic gas detectors with flammable gas sensors detect the presence of such gases, enabling workers to evacuate the area and prevent potential disasters.

Portable Detectors For On-The-Go Safety

- Convenience: Electronic gas detectors are designed to be portable, allowing workers to carry them easily wherever they go. These handheld devices are compact and lightweight, ensuring on-the-go safety without hindering mobility.

- Real-time Monitoring: With real-time gas monitoring capabilities, portable detectors continuously analyze the air quality and provide instant alerts if any hazardous gases are detected. This enables quick decision-making and the implementation of necessary safety protocols to avoid potential hazards.

- User-friendly Interface: Electronic gas detectors come with user-friendly interfaces, featuring clear displays and intuitive controls. This ensures that workers can easily understand the device readings and take prompt action in case of gas detection, minimizing the risk of accidents.

- Battery Life: Portable gas detectors are equipped with long-lasting batteries, ensuring uninterrupted usage during work shifts. This eliminates the need for frequent recharging, allowing workers to focus on their tasks without worrying about device power.

In construction and mining sites, the detection of harmful gases in confined spaces is of utmost importance to ensure the safety of workers. Electronic gas detectors provide a reliable solution, enabling the identification of gases such as carbon monoxide, hydrogen sulfide, and flammable gases.

These portable devices offer convenience, real-time monitoring, user-friendly interfaces, and long battery life, promoting on-the-go safety. By utilizing electronic gas detectors, companies can prioritize the well-being of their employees and maintain a secure work environment while minimizing the risk of gas-related accidents.

Internet Of Things (Iot) Integration

Integrating electronic gas detectors with the Internet of Things (IoT) enables real-time monitoring and seamless communication for enhanced safety and efficiency. This integration empowers businesses to proactively detect gas leaks and respond swiftly to prevent potential hazards.

Electronic Gas Detectors:

The rapid advancement of technology has revolutionized the way we live and work. One such technological marvel that has made its way into various industries is the Internet of Things (IoT). In the realm of gas safety, the integration of IoT with electronic gas detectors has brought about a multitude of benefits.

Let’s delve into how this integration enhances connectivity, enables data sharing capabilities, and facilitates predictive maintenance and analytics.

Enhanced Connectivity And Data Sharing Capabilities:

- Real-time monitoring: With IoT integration, electronic gas detectors can provide real-time updates on gas levels, enabling immediate actions to be taken in case of any abnormalities.

- Remote access: IoT-enabled gas detectors allow for remote monitoring of gas levels, providing convenience and flexibility to users who can now check the status of their gas detection system from anywhere, at any time.

- Seamless integration: IoT integration allows gas detectors to seamlessly connect with other devices and systems, fostering effective collaboration and streamlined workflow.

- Centralized data storage: Gas detection data can be securely stored in the cloud, making it easily accessible for analysis and reporting purposes.

- Data sharing and collaboration: IoT integration facilitates the sharing of gas detection data among relevant stakeholders, promoting collaboration and the collective effort to ensure safety.

Predictive Maintenance And Analytics:

- Early warning system: IoT integration enables the collection and analysis of data from gas detectors, allowing for the identification of patterns and anomalies that may indicate potential gas leaks or equipment failures. This early warning system helps prevent hazardous situations and minimizes downtime.

- Proactive maintenance: By leveraging the power of IoT, gas detectors can proactively notify maintenance personnel about any potential issues, enabling timely interventions and minimizing the risk of equipment failure.

- Predictive analytics: IoT-enabled gas detectors collect and analyze data, generating valuable insights that can aid in predicting maintenance needs, optimizing resource allocation, and identifying areas for process improvement.

- Cost efficiency: The predictive maintenance approach made possible by IoT integration helps organizations reduce unplanned maintenance costs, prevent equipment breakdowns, and enhance operational efficiency.

The integration of IoT with electronic gas detectors brings about enhanced connectivity, data sharing capabilities, and predictive maintenance benefits. With real-time monitoring, remote access, and centralized data storage, gas safety is taken to a whole new level. Moreover, through predictive analytics and proactive maintenance, businesses can ensure operational continuity while minimizing risks and improving cost efficiency.

Embracing IoT integration in gas detection systems is a step towards a safer and smarter future.

Artificial Intelligence (Ai) In Gas Detection

Gas detection systems are now incorporating the power of Artificial Intelligence (AI) to enhance electronic gas detectors. This advanced technology improves accuracy and quickens response times, making gas detection more efficient and reliable.

With the rapid advancements in technology, gas detection devices have incorporated artificial intelligence (AI) to enhance their accuracy and functionality. The integration of AI brings numerous benefits to electronic gas detectors, such as machine learning algorithms for improved accuracy and real-time pattern recognition.

Machine Learning Algorithms For Improved Accuracy:

- Utilizing machine learning algorithms allows gas detectors to continuously learn and adapt to different environments, resulting in more accurate readings.

- These algorithms analyze vast amounts of data to identify patterns and correlations, enabling the detectors to differentiate between harmless gases and potential hazards.

- By continuously learning and updating their knowledge base, gas detectors equipped with machine learning algorithms significantly reduce false alarms and provide more reliable results.

Real-Time Pattern Recognition:

- AI-powered gas detectors can recognize and analyze complex patterns in real time, detecting even the slightest changes in gas concentration levels.

- This real-time pattern recognition enables immediate response and action, leading to enhanced safety measures and potential avoidance of hazardous situations.

- The detectors can identify abnormal gas behavior and trigger alerts, allowing for quick intervention and preventive measures to be taken.

The integration of AI in gas detection devices has revolutionized the way we approach gas safety. These intelligent systems have proven to be highly effective in providing accurate readings and timely warnings, minimizing the risk of gas-related accidents. The use of machine learning algorithms and real-time pattern recognition further enhances the capabilities of electronic gas detectors, making them more efficient and reliable than ever before.

Miniaturized Gas Detectors

Miniaturized gas detectors have revolutionized electronic gas detection by providing compact and efficient solutions for detecting hazardous gases accurately and in real-time. These detectors offer convenience and reliability, making them a preferred choice for various industries and applications.

Advancements In Sensor Technology

Miniaturized gas detectors have become increasingly popular due to advancements in sensor technology. These small and portable devices are designed to detect the presence of various gases in the environment and provide real-time alerts to ensure safety. Here are some key points to understand these advancements:

- Enhanced Accuracy: Miniaturized gas detectors utilize advanced sensor technology to provide highly accurate gas detection. These sensors are capable of detecting low levels of gas concentration, allowing for quick and precise measurements.

- Improved Sensitivity: The advancements in sensor technology have enabled miniaturized gas detectors to become more sensitive. They can detect even the smallest traces of gases, ensuring reliable detection in various applications.

- Faster Response Time: With improved sensor technology, miniaturized gas detectors can provide faster response times. In hazardous situations, every second counts, and these devices can quickly alert individuals to potential gas leaks or dangerous levels of gases.

- Compact Design: One of the notable features of miniaturized gas detectors is their compact and lightweight design. They are smaller than traditional gas detectors, making them easy to carry and wear.

- Wireless Connectivity: Many miniaturized gas detectors are equipped with wireless connectivity, allowing for seamless integration with other devices or systems. This enables data sharing, remote monitoring, and centralized control, enhancing overall safety measures.

- Longer Battery Life: Another advancement in sensor technology is the improved battery life of miniaturized gas detectors. With longer-lasting batteries, these devices can provide continuous monitoring for extended periods, reducing the need for frequent charging or battery replacements.

- Low Maintenance: Miniaturized gas detectors are designed to be low maintenance, requiring minimal calibration and servicing. This reduces downtime and ensures that the devices are readily available for use at all times.

- Cost-effective: The advancements in sensor technology have also contributed to the increasing affordability of miniaturized gas detectors. They offer a cost-effective solution for gas detection in various industries and applications.

The advancements in sensor technology have revolutionized the field of gas detection, leading to the development of miniaturized gas detectors. These devices offer enhanced accuracy, improved sensitivity, faster response times, and a compact design. With wireless connectivity, longer battery life, low maintenance, and cost-effectiveness, miniaturized gas detectors are becoming an essential tool in ensuring safety across various sectors.

Frequently Asked Questions On Electronic Gas Detectors

Do Electronic Gas Leak Detectors Work?

Yes, electronic gas leak detectors are effective in detecting gas leaks and ensuring safety.

What Is A Electronic Gas Detector?

An electronic gas detector is a device that uses sensors to detect the presence of gases in an area.

Is There A Device That Can Detect A Gas Leak?

A gas leak detection device is available that quickly identifies and alerts you to gas leaks.

What Is The Best Detector For Natural Gas?

The best detector for natural gas is one that is accurate, reliable, and has high sensitivity.

Conclusion

Overall, electronic gas detectors have revolutionized the way industries ensure safety and prevent accidents caused by hazardous gases. With their advanced features and capabilities, these devices provide real-time monitoring, accurate measurements, and instant alerts, enabling prompt action and mitigating potential risks.

The versatility of electronic gas detectors allows them to be used across various industries, including oil and gas, mining, chemical, and manufacturing. Their compact size, portability, and ease of use make them invaluable tools in both industrial and personal settings.

Moreover, electronic gas detectors play a crucial role in complying with safety regulations and standards, protecting workers’ well-being, and safeguarding the environment. By detecting and preventing gas leaks, these devices minimize the chances of explosions, fires, and health hazards. Investing in electronic gas detectors is a proactive step towards creating a safer working environment that prioritizes the well-being of employees while ensuring compliance with safety regulations.

With their efficiency, accuracy, and reliability, these devices have become an essential aspect of the modern industrial landscape.