Water leak detection for industrial facilities is essential to prevent costly damages and ensure operational efficiency. This article explores the importance of identifying and resolving water leaks promptly in industrial settings and discusses various methods and technologies utilized for effective detection.

It also highlights the potential consequences of undetected leaks, such as water wastage, property damage, and increased utility bills. By implementing appropriate leak detection systems and regularly monitoring water consumption, industrial facilities can minimize the environmental impact, conserve resources, and save money in the long run.

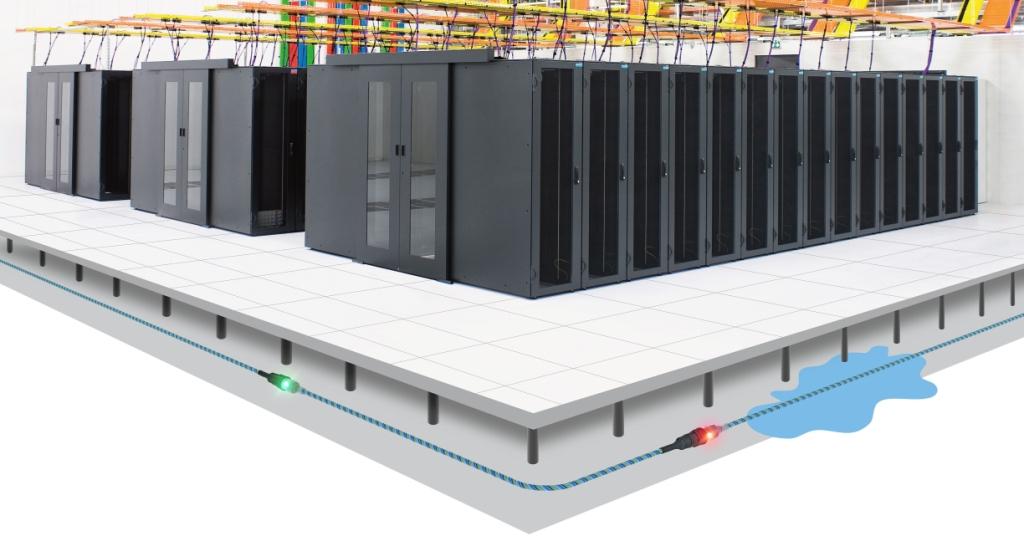

Credit: www.akcp.com

Why Water Leak Detection Is Vital For Industrial Facilities

Water leak detection is crucial for maintaining the efficiency and safety of industrial facilities. Detecting leaks early can prevent costly damage and disruptions to operations, ensuring a smooth and reliable water supply. Trusting in robust water leak detection systems is vital for industrial facility management.

Water leaks can have severe consequences in industrial facilities, causing significant damage and incurring substantial costs. It is crucial for such facilities to have effective water leak detection systems in place to identify and address issues before they escalate. In this section, we will explore the importance of preventing water leaks in industrial facilities, the potential damages and costs associated with them, and how water leak detection systems can help mitigate these risks.

Importance Of Preventing Water Leaks In Industrial Facilities:

- Water leaks can lead to substantial property damage, affecting the structure of buildings, equipment, and machinery.

- Excessive moisture caused by leaks can promote the growth of mold and mildew, which can be harmful to employees and compromise indoor air quality.

- Leaks can result in the deterioration of electrical systems, risking equipment failure and potential safety hazards.

- Water leaks can disrupt normal operations, causing production delays, downtime, and financial losses.

- Additionally, leaks can contribute to the wastage of water, a valuable resource, and increase utility costs.

Potential Damages And Costs Associated With Water Leaks:

- Structural damage: Leaks can weaken the foundation, walls, and floors of industrial facilities, compromising their stability and requiring extensive repairs.

- Equipment damage: Water leaks can damage machinery, electronic systems, and other equipment, resulting in costly repairs or replacements.

- Product loss: Leaks can damage stored inventory, raw materials, or finished goods, leading to financial losses and potential supply chain disruptions.

- Increased energy consumption: Water leaks can cause equipment to work harder or inefficiently, resulting in higher energy consumption and increased utility bills.

- Environmental compliance: Water leaks can lead to environmental compliance issues, fines, or legal actions, particularly if they contaminate water bodies or nearby ecosystems.

How Water Leak Detection Systems Can Help Prevent Costly Damages:

- Early detection: Advanced water leak detection systems can identify leaks at their initial stages, allowing prompt repairs and minimizing potential damages.

- Continuous monitoring: These systems provide real-time monitoring, allowing facility managers to respond immediately to any signs of water leakage, preventing further escalation.

- Reduced downtime: By addressing leaks before they cause significant damage, water leak detection systems help mitigate the risk of production disruptions and minimize downtime.

- Cost-effective: Investing in water leak detection systems can save industrial facilities money in the long run by avoiding costly repairs, production delays, and replacements.

- Efficient resource management: By detecting and repairing leaks promptly, these systems promote efficient water management, reducing wastage and utility costs.

Water leak detection is vital for industrial facilities to prevent extensive damages and costly consequences. By implementing effective leak detection systems, facilities can detect issues early, reduce downtime, and ensure a safe and efficient operation while minimizing financial losses.

Common Causes Of Water Leaks In Industrial Facilities

Water leaks in industrial facilities can cause significant damage and disrupt operations. Detecting water leaks early is crucial to prevent further damage, avoid costly repairs, and ensure the smooth running of operations in these facilities.

Corrosion And Aging Pipes

- Industrial facilities often have extensive pipe systems that carry water for various purposes. Over time, these pipes can deteriorate due to natural processes like corrosion. Corrosion occurs when the metal surfaces of the pipes react with the substances in the water, leading to the gradual degradation of the pipes.

- Corroded pipes are more prone to developing leaks, increasing the risk of water damage and operational disruptions in industrial facilities.

- The corrosion process can be further accelerated by factors such as high water acidity, elevated temperatures, and the presence of corrosive chemicals in the water supply.

Faulty Or Damaged Seals And Gaskets

- Seals and gaskets play a crucial role in preventing water leakage in industrial facilities. They are used to create a watertight seal between two connecting parts, such as pipes, valves, or equipment.

- Over time, seals and gaskets can deteriorate, becoming faulty or damaged. This can happen due to wear and tear, exposure to harsh chemicals, high pressure, or incompatible materials.

- Faulty seals and gaskets can result in water leaks, compromising the integrity of the entire system. Detecting and addressing issues with these components is essential to prevent water leaks in industrial facilities.

High Water Pressure

- In industrial facilities, water is often supplied at high pressures to accommodate various processes and equipment. While this may be necessary, it can also contribute to water leakages if not properly regulated.

- Excessively high water pressure can put strain on the pipe system, causing joint failures or pipe bursts, leading to significant water loss and potential damage.

- Monitoring and controlling water pressure within recommended limits is crucial to prevent excessive stress on pipes and minimize the risk of water leaks in industrial facilities.

Poor Installation Or Maintenance

- Inadequate installation or maintenance practices can be a major cause of water leaks in industrial facilities. Improper connections, loose fittings, or incorrect assembly of components can result in weak points within the system.

- Lack of regular maintenance, including inspection and repairs, can exacerbate these issues. Over time, small leaks may develop and worsen if not promptly addressed.

- Proper installation and regular maintenance are essential to ensure the integrity of the water systems in industrial facilities, minimizing the chances of water leaks and related problems.

Types Of Water Leak Detection Systems For Industrial Facilities

Industrial facilities can benefit from various types of water leak detection systems. These systems provide efficient monitoring and early detection of leaks, helping to prevent costly damages and downtime. From acoustic sensors to flow sensors, there are many options available to ensure the safety and reliability of water infrastructure in industrial settings.

Water leaks can be a significant problem for industrial facilities, leading to wasted resources, increased costs, and potential damage to equipment. Implementing a water leak detection system is crucial to identify and address leaks promptly, minimizing the negative impact they can have.

In this blog post, we will explore the different types of water leak detection systems available for industrial facilities.

Passive Leak Detection Systems

Passive leak detection systems are designed to detect water leaks through the presence of water or changes in pressure or humidity. Here are some key points to know about passive leak detection systems:

- Water sensors: These systems utilize water sensors placed at strategic locations to detect the presence of water. When water is sensed, an alarm is triggered to alert facility personnel. This system can be effective in areas prone to leaks, such as near pipes, tanks, or equipment.

- Pressure sensors: Some passive systems use pressure sensors to monitor changes in water pressure. If a sudden drop in pressure is detected, it can indicate a leak in the system. This approach is useful for identifying leaks in large pipelines or pressurized systems.

- Humidity sensors: Humidity-based detection systems monitor changes in humidity levels. When an abnormal increase in humidity is detected, it may indicate the presence of a water leak. This type of system is particularly useful in areas where moisture-related issues may occur, such as storage rooms or basements.

Pros of passive leak detection systems include:

- Continuous monitoring: These systems provide continuous monitoring, ensuring that any potential water leaks are promptly detected.

- Cost-effective: Passive leak detection systems are often more cost-effective than active systems, as they do not require extensive installation or maintenance.

- Early leak detection: By detecting leaks at an early stage, passive systems can prevent further damage and potential downtime.

Examples and applications of passive leak detection systems:

- Water sensors can be installed in server rooms to protect valuable equipment from potential water damage caused by leaks.

- Pressure sensors can be implemented in large-scale irrigation systems to detect leaks in underground pipes and prevent water waste.

- Humidity sensors can be utilized in commercial kitchens to identify potential plumbing leaks that may lead to mold growth.

Active Leak Detection Systems

Active leak detection systems involve the use of actively controlled components to identify water leaks. Here are some important aspects of active leak detection systems:

- Flow monitoring: Active systems monitor water flow rates and can identify deviations that may indicate a leak. By comparing the current flow rate to the expected flow rate, these systems can quickly detect and alert personnel of potential leaks.

- Water shut-off valves: Some active systems incorporate automatic shut-off valves that can be activated upon detecting a leak. This feature helps minimize water loss and damage, as the water supply is immediately cut off once a leak is identified.

- Real-time alerts: Active systems can send real-time alerts to facility personnel via email, SMS, or a centralized monitoring system. This allows for immediate action to be taken, reducing the impact of leaks.

Pros of active leak detection systems include:

- Rapid response: With real-time alerts and automated shut-off valves, active systems enable swift response to water leaks, minimizing potential damage.

- Enhanced accuracy: Active systems use advanced monitoring techniques, providing accurate identification and location of leaks.

- Versatility: These systems can be customized to suit specific facility requirements, providing flexibility in implementation.

Examples and applications of active leak detection systems:

- Flow monitoring systems can be installed in industrial boiler rooms to identify leaks in the piping network and prevent water wastage.

- Active systems with automatic shut-off valves can be utilized in laboratory settings to protect sensitive equipment and samples from water damage.

- Real-time alert systems can be integrated into manufacturing plants to quickly detect leaks in cooling systems, preventing production line disruption.

Remember, implementing an appropriate water leak detection system in industrial facilities is essential for early identification and mitigation of leaks, minimizing potential damage and cost. Choose a system that aligns with your facility’s specific requirements and conditions to effectively safeguard your operations against water-related issues.

Benefits Of Implementing Water Leak Detection Systems

Industrial facilities can greatly benefit from implementing water leak detection systems. These systems help in detecting leaks early, saving resources and minimizing damage to equipment and infrastructure. With timely detection, businesses can reduce water wastage, lower repair costs, and maintain smooth operations.

Water leaks can cause significant damage to industrial facilities and result in costly repairs, wasted resources, and potential non-compliance with environmental regulations. Implementing water leak detection systems can provide various benefits that help mitigate these risks. Let’s explore them:

- Early detection and prevention of water leaks: Water leak detection systems are designed to identify leaks at their earliest stages, enabling prompt action to limit the damage. These systems utilize advanced technology to detect leaks in pipes, tanks, valves, and other components, ensuring that potential issues are addressed before they escalate into major problems.

- Minimization of damage to equipment, infrastructure, and products: Water leaks can cause extensive damage to industrial equipment, infrastructure, and stored products. By implementing water leak detection systems, businesses can minimize the risk of damage caused by leaks. This proactive approach not only saves on costly repairs but also helps maintain the integrity of the facility’s equipment and infrastructure, ensuring uninterrupted operations.

- Cost savings in repairing damages and water wastage: Detecting and repairing water leaks in a timely manner can lead to significant cost savings. By identifying leaks early on, businesses can avoid expensive repairs and prevent further damage to the facility or products. Moreover, minimizing water wastage through efficient leak detection helps reduce utility expenses, leading to overall cost savings for the organization.

- Compliance with environmental regulations: Industrial facilities must adhere to strict environmental regulations regarding water usage and conservation. Implementing water leak detection systems allows businesses to monitor water consumption and promptly address any leaks or inefficiencies. By ensuring compliance with environmental regulations, companies can avoid penalties and demonstrate their commitment to sustainable practices.

Implementing water leak detection systems in industrial facilities offers numerous advantages, including early leak detection and prevention, minimizing damages, cost savings, and compliance with environmental regulations. These systems provide businesses with the tools to proactively address water leaks, safeguard their assets, and reduce the environmental impact of their operations.

Factors To Consider When Choosing A Water Leak Detection System

Choosing the right water leak detection system for industrial facilities requires careful consideration of various factors. Factors such as accuracy, reliability, ease of installation, and system integration should be taken into account to ensure efficient and effective detection of leaks in industrial settings.

Water Leak Detection For Industrial Facilities

Water leaks in industrial facilities can cause significant damage, leading to financial losses and disruptions in operations. This is why investing in an effective water leak detection system is crucial. When choosing the right system for your facility, there are several factors to consider to ensure optimal functionality and protection against water damage.

Facility Size And Layout

The size and layout of your industrial facility play a vital role in determining the type of water leak detection system you need. Consider the following:

- Facility size: A larger facility may require a system that can cover a wide area, such as a network of multiple sensors or a continuous monitoring system.

- Layout complexity: If your facility has complex architecture with multiple levels or segmented areas, you may need a system that can be easily installed and customized to monitor each specific zone.

Type Of Water Supply System

Different industrial facilities have varying water supply systems. It’s important to take into account the specific requirements of your system:

- Piped water supply: If your facility relies on a piped water supply system, you’ll need a detection system that can monitor the flow of water through the pipes and detect any leaks.

- Sprinkler systems: If your facility has a sprinkler system for fire protection, it’s crucial to choose a leak detection system that can quickly identify and alert you to any leaks in the sprinkler pipes.

Required Sensitivity And Accuracy

The sensitivity and accuracy of a water leak detection system are vital to its effectiveness. Consider the following factors:

- Early detection: Look for a system that can detect even the smallest leaks to ensure early detection and prevent potential damage.

- False alarms: Choose a system that minimizes false alarms to avoid unnecessary disruptions in operations and maintenance efforts.

Integration With Existing Facility Management Systems

To streamline operations and enhance efficiency, it’s essential to choose a water leak detection system that can integrate with your existing facility management systems. Consider the following:

- Building management systems: If your facility operates with a centralized building management system, opt for a leak detection system that can seamlessly integrate with it to provide centralized monitoring and control.

- Alerting and reporting: Choose a system that can generate real-time alerts and comprehensive reports, making it easier for facility managers to respond promptly and efficiently.

Cost And Budget Considerations

When investing in a water leak detection system, it’s crucial to consider your budget and the overall cost of ownership. Here are some factors to keep in mind:

- Installation and maintenance: Evaluate the installation requirements and ongoing maintenance costs associated with the system.

- Return on investment: Assess the potential cost savings and damage prevention benefits that the system can provide in the long run.

By considering these factors, you can make an informed decision when choosing a water leak detection system for your industrial facility. Protecting your facility from water damage is essential to maintain smooth operations and minimize financial losses.

Installation And Maintenance Of Water Leak Detection Systems

Ensure the smooth operation of your industrial facility with our expert installation and maintenance services for water leak detection systems. Detect and promptly address potential leaks to prevent costly damage and downtime. Trust our team to keep your facility running efficiently.

Proper Installation Process:

- A proper installation process is key to ensuring the effectiveness and functionality of water leak detection systems in industrial facilities.

- During the installation, it is essential to follow these steps:

- Conduct a thorough assessment of the facility to identify potential leak points and vulnerable areas.

- Select the appropriate system based on the specific needs of the facility.

- Install the sensors at strategic locations, such as around pipes, valves, and other water-related equipment.

- Connect the sensors to the main control panel or monitoring system.

- Perform a comprehensive test to ensure all components are functioning correctly.

Regular Maintenance And Testing Procedures:

- Regular maintenance and testing are vital to keep water leak detection systems in optimal condition and prevent false alarms or system failures.

- Here are some key maintenance and testing procedures:

- Inspect the sensors periodically to check for physical damage or corrosion.

- Clean the sensors to remove any debris or dirt that may interfere with their performance.

- Test the sensors regularly by simulating leaks to verify their responsiveness.

- Calibrate the sensors to maintain accurate detection settings.

- Check the control panel or monitoring system for any software or hardware updates and install them as needed.

Importance Of Trained Personnel For System Monitoring:

- Monitoring water leak detection systems requires trained personnel who understand the intricacies of the system and can respond efficiently in case of emergencies.

- Trained personnel play a crucial role in:

- Monitoring the system in real-time to detect any signs of water leaks or abnormalities.

- Responding promptly to alarms and taking appropriate actions to mitigate further damage.

- Conducting regular system checks to ensure optimal performance.

- Performing troubleshooting procedures in case of system malfunctions.

- Documenting and reporting any incidents, maintenance activities, or repairs for future reference.

Troubleshooting And Repairs:

- Prompt troubleshooting and repairs are essential to maintain the functionality of water leak detection systems and minimize downtime.

- When faced with system issues, the following steps can help identify and resolve the problem efficiently:

- Conduct a thorough investigation to determine the cause of the malfunction.

- Check the sensor connections and ensure they are secure.

- Inspect the control panel or monitoring system for error messages or unusual indicators.

- Refer to the system’s manual or contact the manufacturer for troubleshooting guidelines.

- Perform necessary repairs or, if required, replace faulty components.

- After resolving the issue, conduct post-repair testing to verify system integrity.

Remember, proper installation, regular maintenance and testing, trained personnel for system monitoring, and efficient troubleshooting and repairs are crucial factors in ensuring the effectiveness of water leak detection systems in industrial facilities. By following these guidelines, facility managers can safeguard their assets, prevent water damage, and maintain overall operational efficiency.

Best Practices For Water Leak Prevention In Industrial Facilities

Prevent water leaks in industrial facilities with effective water leak detection practices. Implementing these strategies can help avoid costly damages and maintain smooth operations within the facility.

Industrial facilities often face the risk of water leaks, which can lead to significant damage and costly repairs. By implementing best practices for water leak prevention, companies can minimize the impact of leaks and maintain efficient operations. Here are some key strategies to consider:

Conducting Regular Inspections And Audits:

- Schedule routine inspections of plumbing systems, equipment, and infrastructure to identify potential leaks or weak points.

- Assign trained personnel to conduct thorough audits, checking for water leak signs such as dampness, corrosion, or water stains.

- Use leak detection technology like moisture meters or thermal imaging cameras during inspections to detect hidden leaks.

Implementing Preventive Maintenance Programs:

- Develop a comprehensive preventive maintenance program that includes regular checks, repairs, and replacements of equipment and plumbing components prone to leaks.

- Keep detailed records of maintenance activities, ensuring that any potential leak points are addressed promptly.

- Regularly clean and clear drains, gutters, and downspouts to prevent clogs that can lead to water leakage.

Training Employees On Water Leak Awareness And Reporting:

- Educate and train employees on the importance of water leak prevention and the specific risks associated with leaks in industrial facilities.

- Teach employees how to detect and report water leaks promptly, emphasizing the role of early intervention in minimizing damage.

- Provide training on proper usage and care of equipment and machinery to reduce the likelihood of leaks caused by employee error.

Creating Emergency Response Plans:

- Develop detailed emergency response plans that outline the steps to be taken in the event of a water leak.

- Designate roles and responsibilities for responding to leaks, ensuring that employees know who to contact and what actions to take.

- Establish protocols for shutting off water supply valves and isolating affected areas to contain leaks quickly.

Continuous Improvement And Monitoring Of Water Management Processes:

- Regularly review and improve water management processes, incorporating feedback and lessons learned from past incidents.

- Implement water monitoring systems to detect anomalies in water consumption patterns, which may indicate leaks.

- Conduct regular audits to ensure compliance with water leak prevention protocols and identify areas for improvement.

By following these best practices for water leak prevention, industrial facilities can safeguard their operations, reduce downtime, and protect their assets from water damage. Diligent maintenance, well-trained employees, and effective emergency plans are key to minimizing the impact of water leaks in these settings.

Frequently Asked Questions For Water Leak Detection For Industrial Facilities

What Is The Best Commercial Leak Detection System?

The best commercial leak detection system is one that combines advanced technology and accurate results.

What Are The Systems For Water Leak Detection System For Buildings?

Water leak detection systems for buildings include automated sensors, flow meters, acoustic devices, and thermal imaging cameras.

What Is Used To Locate Leaks In Industrial Pipe Lines?

Industrial pipe lines are located for leaks using specialized equipment such as leak detection systems.

Which Technique Is Used To Detect Water Leakage?

Water leakage can be detected using various techniques such as thermal imaging, acoustic detection, and dye testing.

Conclusion

Effective water leak detection is crucial for industrial facilities to prevent significant damage and financial losses. By implementing state-of-the-art technology and regular monitoring, facility managers can identify and resolve leaks before they escalate into major problems. The utilization of advanced leak detection systems not only helps in reducing water wastage but also contributes to sustainability efforts.

Additionally, proactive leak detection enables companies to comply with regulations and demonstrates their commitment to environmental stewardship. Investing in professional leak detection services ensures that industrial facilities maintain optimal efficiency, minimizes downtime, and avoids costly repairs. By quickly detecting and addressing leaks, businesses can protect their assets, save valuable resources, and enhance their overall operational performance.

Prioritizing water leak detection is a key step towards a more sustainable future while also contributing to the bottom line. Don’t wait until it’s too late – invest in water leak detection solutions to safeguard your industrial facility and the environment.